Introduction

In this installation guide we have provided step by step instructions to remove the OEM front brakes and install the 27WON Performance Big Brake Kit.

Advisory:

- Working under the vehicle requires a safe and sturdy location for the vehicle to sit on jackstands.

- The brake rotors can be hot after recent vehicle operation. Allow the vehicle to cool or use a fan to cool the brake rotors before working on the vehicle.

Tools

- Hydraulic Jack

- Jack Stand × 2

- 3/8" Ratchet

- 3/8" Long Extension

- 12mm Wrench

- 17mm Wrench

- 19mm Wrench

- 12mm Socket

- 14mm Socket

- 17mm Socket - Deep

- 10mm Box-End Wrench

- 17mm Box-End Wrench

- 19mm Box-End Wrench

- 10mm Line Wrench

- 10mm Allen Key Socket

- 1/2" Breaker Bar

- 1/2" Torque Wrench

- Lug Nut Socket

- Phillips Screwdriver - #3

- Phillips Impact Driver

- Hammer

- Tin Snips

- Cut Off Wheel (optional)

- Pry Bar (or Large Screw Driver)

- Vice Grip Pliers

- Locktite, Blue

- Flat Black Spray Paint

- Brake Clean Spray

- Brake Fluid-DOT 3

- WD-40 Lubricant Spray

- Catch Tray

- Shop Towels/Rags

- Brake Bleed Canister w/ Hose

- 5mm Allen Wrench

- 90 Degree Pick Tool

- Flat Head Screwdriver - Large

-

-

First and foremost; THANK YOU for becoming a part of the 27WON Family. We hope to REDEFINE your experience of the aftermarket with the highest level Parts, Customer Service, Packaging, & Support

-

Located at the end of these installation instructions is a How-To Guide for Brake Pad Replacement

-

These instructions were written on a 2005 S2000 with thicker front rotors. Install is similar

-

Trimming of brake dust shields is required to accommodate the caliper brake bracket. See Step 9

-

Provided brake pads are for spirited street use. For track use, different pads are required. See step 29 for recommendations

-

-

-

OE wheels will require the use of wheel spacers for proper clearance and operation

-

Some aftermarket wheels will require the use of wheel spacers for proper clearance and operation

-

Use our Wheel Fitment Guide to check caliper clearance for your wheels: https://store.27won.com/_27Won/27Won-1-P...

-

-

-

These instructions reference the separate sides of the vehicle as "Left Hand" & "Right Hand". Left Hand & Right Hand is always defined from the driver seat viewpoint

-

Brake fluid is corrosive to paint. Do not let brake fluid sit on painted surfaces for extended periods of time

-

-

-

Raise the vehicle and support with jackstands in the OE recommended locations and remove the front wheels/tires

-

The following instructions show the complete removal of OE components and installation of 27WON BBK for the right hand side. The left hand side is completed with the same steps

-

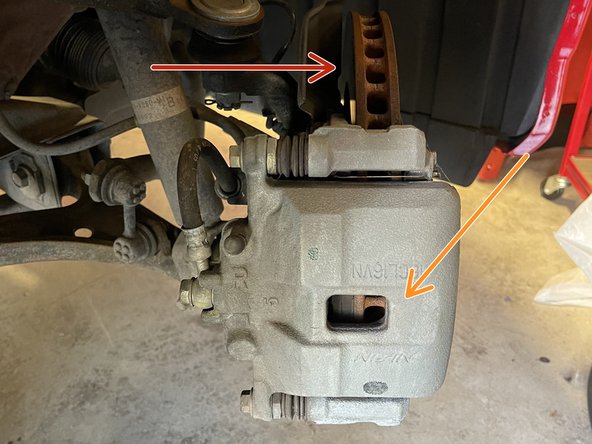

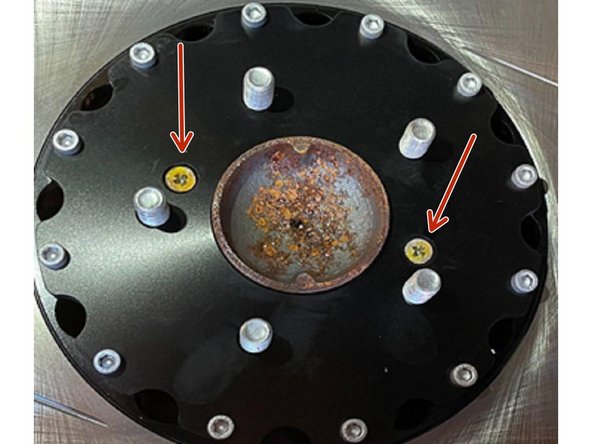

Brake Rotor, see red arrow

-

Brake Caliper, see orange arrow

-

-

-

Using 12mm socket on extension, remove the brake line bracket on the strut

-

Using 12mm socket on extension, remove the brake line bracket on the caliper

-

-

-

Disconnecting the brakeline will allow brake fluid to leak from the hard brakeline mounted to the chassis and the rubber brakeline on the caliper. Use a rag to catch drips

-

Using 12mm socket, disconnect the brake line from the caliper and let it drain into the drain pan

-

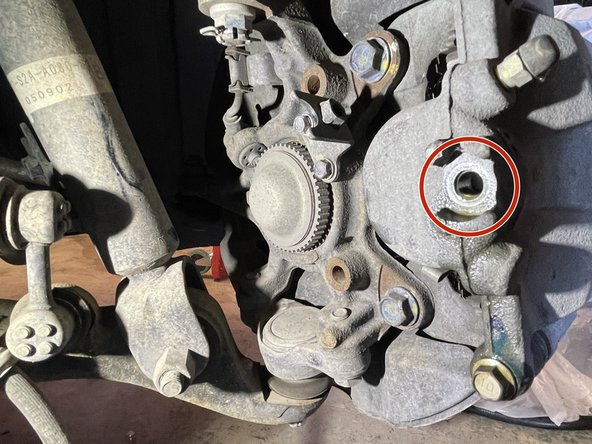

Using a 17mm socket, loosen the caliper bracket bolts holding the caliper to the knuckle

-

Remove the caliper from the knuckle

-

-

-

Remove the (2) Philips screws with an impact driver as shown

-

Remove the brake rotor from the hub

-

If the rotor won't come off, thread an M6x1.00 screw into the threaded holes of the rotor and it will be lifted from the hub

-

-

-

Caliper Brackets

-

Mounting holes to vehicle

-

Mounting holes to BBK Caliper

-

Short Socket Cap Bolts

-

-

-

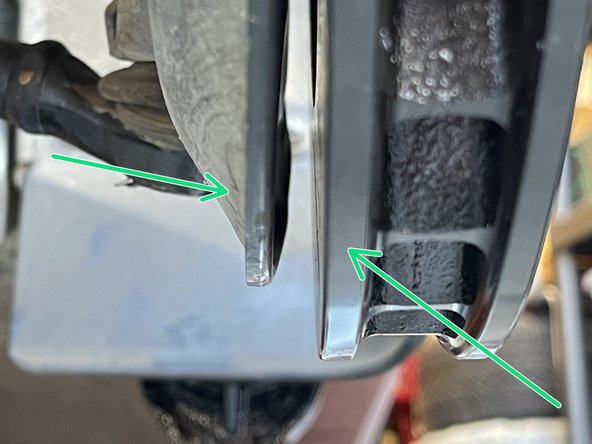

Trimming of brake dust shields is required to accommodate the caliper brake bracket

-

Using Tin snips or cut off wheel, trim the brake dust shield as shown

-

We recommend applying some paint over the exposed metal to prevent corrosion

-

-

-

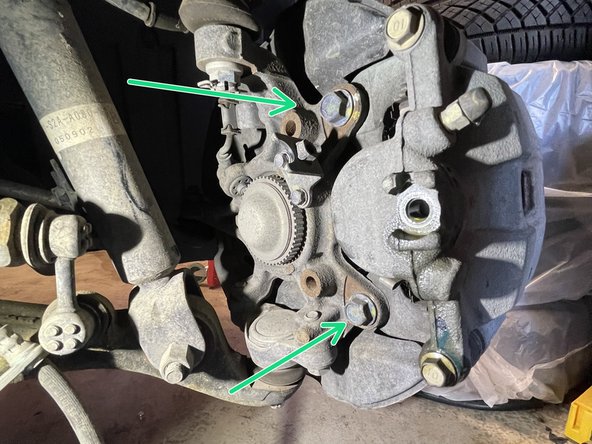

Orient the caliper brackets to the knuckle as shown

-

Apply Loctite to the (2) short cap bolts before installing

-

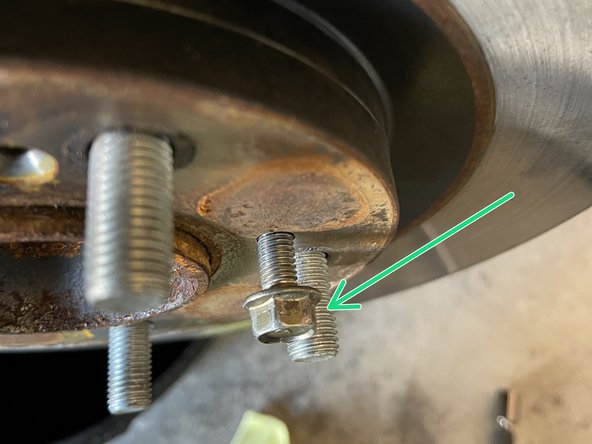

Insert the (2) short socket cap bolts from the backside

-

Using a 10mm Allen key socket and torque wrench, torque to 64-71 ft-lbs

-

-

-

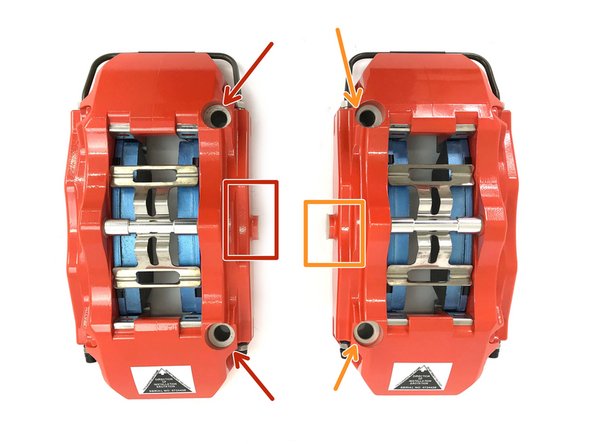

The 27WON BBK has directional brake rotors - therefore it is critical that the correct rotor is installed on the correct side of the vehicle

-

The direction of the angled slots allows you to identify if the rotor is LH or RH

-

Left Hand Rotor (LH) - This rotor will go on the Left Hand side of the vehicle

-

For North American cars this is the driver side

-

Right Hand Rotor (RH) - This rotor will go on the Right Hand side of the vehicle

-

Rotors come with machine oil on them to resist corrosion - clean both rotors with brake cleaner spray and clean rag

-

-

-

Install the rotor by reusing the OEM Phillips screws in the chamfered holes on the rotor as shown

-

Right side rotor shown in image above. For US model cars this is the passenger side. Driver side similar

-

Inspect the dust shield to verify it’s not touching the rotor. If it is, bend it away slightly using a large screw driver or pry bar

-

-

-

27WON BBK has directional brake calipers - therefore it is critical that the correct caliper is installed on the correct side of the vehicle

-

Left Hand Caliper - This caliper will go on the Left Hand side of the vehicle

-

For North American cars this is the driver side

-

Right Hand Caliper - This caliper will go on the Right Hand side of the vehicle

-

Long Socket Cap Bolts

-

Included with the hardware is a pack of very thin washers. These are used as spacers for the rare case that the position of the caliper needs to be adjusted

-

-

-

Locate the provided stainless steel braided brakelines

-

Caliper side of brakeline w/blue dust cover

-

Chassis side of brakeline w/blue dust cover

-

Rubber Strut Mount Isolators

-

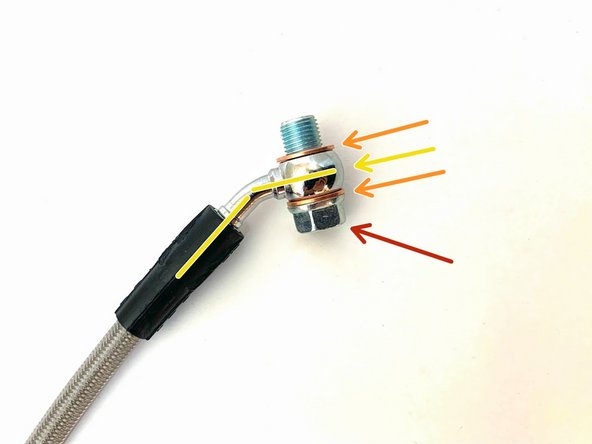

Locate the provided Banjo Bolts

-

Locate the provided 10mm Crush Washers

-

-

-

Add some thread locker to the provided caliper bolts

-

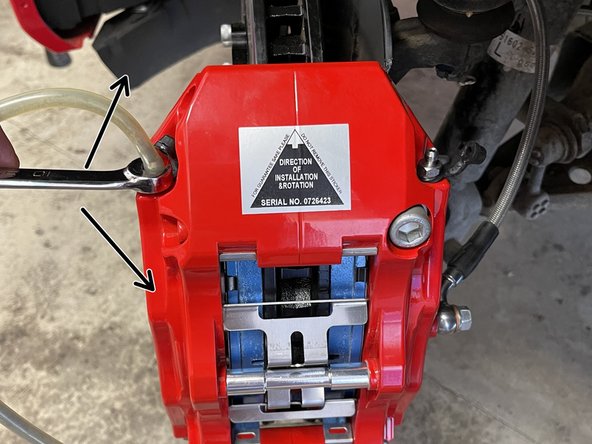

Ensure the bleeders are pointing up when installing your 27WON calipers as shown

-

Install the caliper to the caliper bracket using a 10mm Allen key and bolts provided

-

Torque the bolts to 64-71 ft-lbs

-

-

-

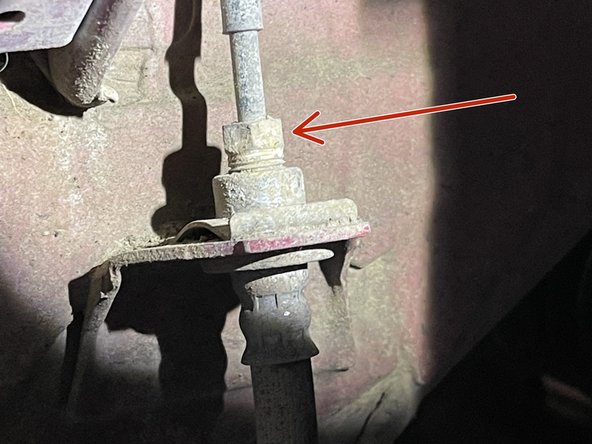

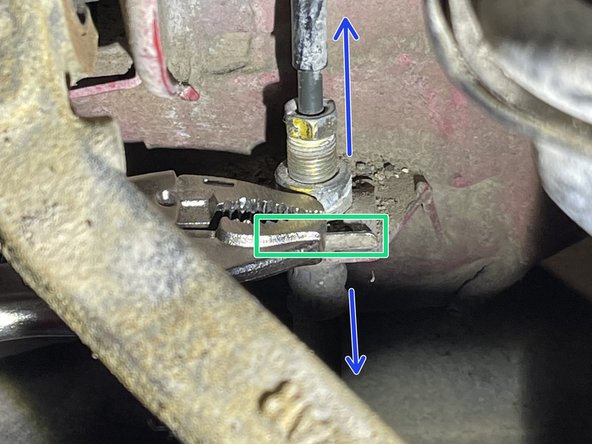

Using a line wrench, loosen the 10mm flare nut for the brake hardline

-

Use small vice grip pliers to remove the mounting clip holding the OEM brake line

-

Separate both sides of the brake line from each other

-

-

-

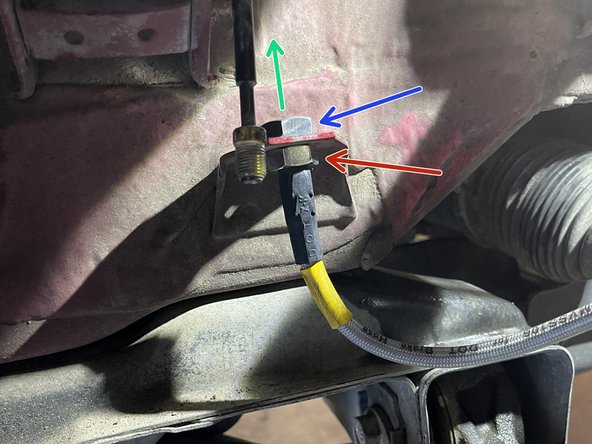

Take one of the provided brake lines and remove the blue plastic dust cover from the brakeline

-

Remove the large 19mm nut from the same brakeline

-

Route the brake line through the chassis mounting bracket as shown

-

Tighten the top nut with a 19mm wrench

-

Once the line is held by the top nut, secure the line with a 17mm wrench on the bottom nut

-

Tighten both nuts down

-

-

-

Install the OEM hardline into the 27WON brakeline as shown

-

Tighten with a 10mm line wrench line

-

-

-

Using the OEM 12mm bolts, install a provided brake line bracket onto the strut as shown. Torque down to 10-14 ft-lbs

-

Install brake line into the provided brake line bracket. Lubricate the grommet if needed

-

-

-

Line up the banjo bolt with the washers and brake line as shown

-

Install the front brake line into the front caliper using the supplied banjo bolt and (2) crush washers

-

Using a 14mm socket and torque wrench - torque to 8-12 ft-lbs

-

-

-

This completes the BBK installation for the right hand side of the vehicle. The left hand installation process is the same

-

Complete the left hand installation process starting on Step 4

-

-

-

Do not proceed until brake kit is installed on both sides

-

Top off your fluid in the reservoir using Honda recommended DOT 3 brake fluid

-

Ensure throughout the brake bleeding procedure that you monitor the brake fluid level and don’t let the reservoir become completely empty

-

-

-

This completes the installation of the physical BBK. It's now necessary to bleed the brakes and bed the brake pads. The following steps provide instruction for brake bleeding and brake pad bedding

-

Located at the end of the installation instructions is a How-To Guide for Brake Pad Changes

-

-

-

Both Left Hand and Right Hand BBK Systems must be installed completely before proceeding to the Brake Bleeding Procedure

-

Clean all brakeline connections at chassis and caliper with brake clean spray and clean rag

-

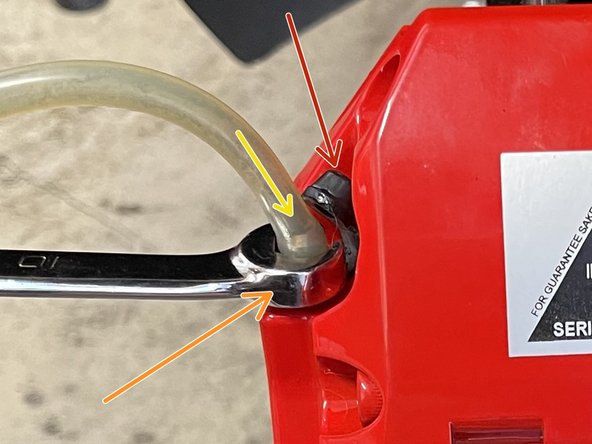

Tools - You will need a fresh container of DOT 3 Brake Fluid, bleeder bottle and hose as shown (the hose should fit tight on the bleeder screw), 10mm box-end wrench, and a friend to help with the process

-

For best results, always start with the bleed screw located the furthest away from the master cylinder and work your way closer. There are two bleed screws for each caliper. Follow the order below

-

First Bleed Screw - RH Outside

-

Second Bleed Screw - RH Inside

-

Third Bleed Screw - LH Outside

-

Last Bleed Screw - LH Inside

-

-

-

Remove the cap from the bleed screw as shown

-

Place the wrench over the bleed screw hex as shown

-

Put one end of the hose on the bleed screw as shown

-

Hang the bottle from a wheel studs or set it on the ground

-

Have yourself or your friend setup in the driver's seat so that they can press the brake pedal firmly

-

Have the other person setup at the brake caliper so they can open/close the bleed screw

-

To open/close the bleed screw - you only need to turn the wrench ~1/4 turn

-

-

-

Have the person in the driver's seat press the brake pedal 3-5 times until there is sufficient pedal pressure. Then, have them hold the brake pedal firmly as the bleed screw is loosened. The pedal will go to the floor while fluid and air will enter the bottle. Make sure your friend holds the pedal down as you retighten the bleed screw.

-

The brake pedal will go to the floor while fluid and air will be pushed through the open bleed screw

-

Continue holding the brake pedal down until the bleed screw is re-tightened/closed

-

Repeat the above procedure around 3-5 times per bleed screw, or until your are confident there is no air in the system Check that your brake fluid level is at “full” after each bleed screw.

-

After each bleed screw is completed, check that your brake fluid level is at “full”. Refill as needed

-

Move to the next bleed screw as listed in Step 24 until all four bleed screws have been completed

-

Once brake bleeding is complete, inspect all brakeline connections at chassis and caliper to verify there are no leaks

-

-

-

If the brakes are properly bleed the brake pedal should have distinct "feel" to it

-

Brake pedal should have minimal down travel before pressure/force is felt

-

Brake pedal should feel firm after a small amount of down travel - it should not feel "spongy" or loose pressure over a quick amount of time

-

If your brake pedal does not correlate with the above, then go through the brake bleeding procedure again

-

-

-

Brake pad bedding is an essential process to the life and durability of the brake pads and rotors - for optimal BBK performance please follow the steps below

-

Proper pad bedding slowly heats and cools the rotors & pads - do not hard brake during initial driving until after complete bedding procedure is complete

-

Find an open road and accelerate to 30mph - Brake evenly and smoothly at ~50% effort until the vehicle is almost stopped, then accelerate to 30mph again

-

Repeat above step 8-10 times

-

Find an open road and accelerate to 50mph - Brake evenly and smoothly at ~80% effort until the vehicle is almost stopped, then accelerate to 50mph again

-

Repeat above step 2-3 times

-

Allow ~15min for brakes to cool - You can now use the brakes for normal driving

-

-

-

All braking systems are a compromise of Performance, Dust, and Noise. These factors are all highly dependent on the brake pad material used

-

The 27WON BBK arrives to your door with a brake pad material we found to be a good compromise of the above three factors. The pad material is consider a "street sport" setup that will provide a low amount of dust, nearly zero noise (some noise if very cold), and good performance for most street driven applications

-

The 27WON BBK is designed around a very common pad size and shape. If desired you may seek out a brake pad compound that better suits your driving style and application

-

Brake Pad Options by Manufacturer - There are many more options available than shown

-

Hawk - HB110.654

-

Carbotech - CTCP2279

-

G-Loc - GPX6

-

-

-

This completes the installation & setup of your 27WON Performance Front Big Brake Kit

-

We hope you were impressed with your 27WON experience and love your new BBK for years to come. Email us at sales@27won.com or call us at 571-271-0271 with any questions or concerns

-

Please Leave a review here: https://store.27won.com/2000-2009-honda-...

-

Share your experience using #27WON on Instagram and Facebook

-

Proceed to the next step for the How-To Guide for Brake Pad Replacement

-

-

-

These instructions were written on a Honda Civic. Steps for the 27WON BBK on a S2K are the same

-

Using a 5mm Allen wrench, remove the caliper bridge bolt

-

While loosening the bolt, push on the bridge spacer towards the rotor then remove the bolt

-

Remove bridge spacer and spring clip

-

Using a flathead screwdriver, push the brake pad away from the rotor as shown to provide clearance

-

Typically the brake pad backer plate has a small edge that can be pushed against

-

Locate the 90 degree pick tool for the next step

-

-

-

Using a 90deg pick tool, hook the pick on the backer plate of the brake pad then remove brake pad

-

Pull the top and bottom of the brake pad in even increments until the pad can be fully removed

-

With the brake pad removed you can now access the caliper pistons directly - you will need to fully press the pistons into the caliper to provide clearance for new brake pads

-

Sometimes while pressing one piston in, another piston will push out. If necessary, hold the other pistons in place while pressing a piston into the caliper

-

-

-

Install the new brake pad into the caliper as shown

-

Verify the brake pad material surface is towards the rotor face and the backer plate is towards the pistons

-

Repeat Step 31 & 32 for the remaining used brake pad

-

Re-install the brake pad spring clip and the caliper bridge spacer - hand thread the caliper bridge bolt and torque to 8-10 ft-lbs

-

Complete the Brake Pad Bedding Procedure in Step 28

-