Introduction

In this installation guide we have provided step by step instructions to remove the OEM downpipe and install the 27WON Performance downpipe.

Advisory:

- Non-Catted Downpipes are strictly intended for racing use only.

- Working under the vehicle requires a safe and sturdy location for the vehicle to sit on jackstands.

- The exhaust piping, turbocharger, and cooling system will be hot after recent vehicle operation. Allow the vehicle to cool or use a fan to cool the exhaust components before working on the vehicle.

Tools

- Silicone Lubricant Spray

- WD-40

- Shop Towels/Rags

- Jack Stand × 2

- Hydraulic Jack

- Flat Head Screwdriver - Large

- Phillips Screwdriver - #2

- Tongue and Groove Adjustable Pliers

- Needle Nose Pliers

- Socket 5.5mm

- Socket, 10mm

- Socket 12mm

- Socket 14mm

- Ratchet Wrench Extension - Short

- Ratchet Wrench Extension - Long

- Ratchet Wrench

- Wrench, 10mm

- Wrench, 12mm

- Wrench, 14mm

- Wrench, 19mm

- 5mm Allen Wrench

- Torque Wrench

- O2/Oxygen Sensor Socket

- Magnet on a Stick

-

-

First and foremost; THANK YOU for becoming a part of the 27WON Family. We hope to REDEFINE your experience of the aftermarket with the highest level Parts, Customer Service, Packaging, & Support

-

If you are installing a 27WON Front-Pipe along with the Downpipe, please see the Front-Pipe Instructions Here: http://store.27won.com/support/instructi...

-

Defouler & Non-Catted Downpipes are strictly intended for racing use only. Installation and use are at the customers own risk

-

Heat shield fitment may be different outside North America. Some modification of heat shield may be required for proper fitment.

-

-

-

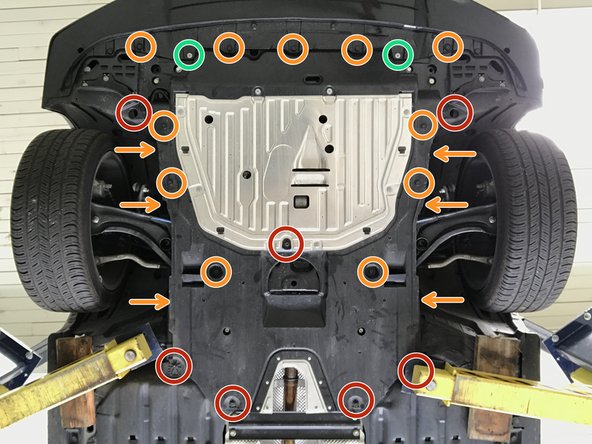

Locate the engine skidtray to gain access to the downpipe and front-pipe

-

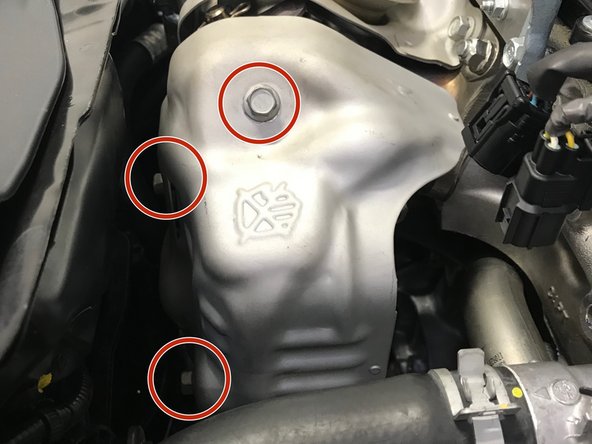

Use 5mm Allen to remove the two (2) bolts shown in green circles

-

Use 10mm socket & ratchet to remove the seven (7) bolts shown in red circles

-

Use a flathead screwdriver to remove the seventeen (17) plastic push-clips. Orange arrows identify the push-clips described in the next step (3)

-

-

-

Use large flat head screw driver to remove push-clips on each side of skidtray

-

-

-

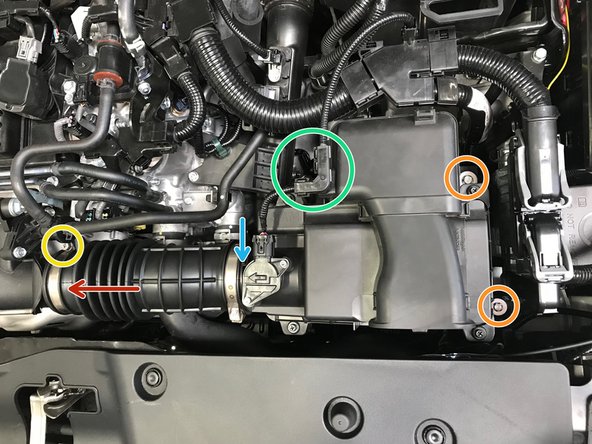

Disconnect the wiring harness from the MAF Sensor

-

Remove the wire cover from the airbox

-

Use needle nose pliers to pinch the clips then pull the cover off the airbox

-

-

-

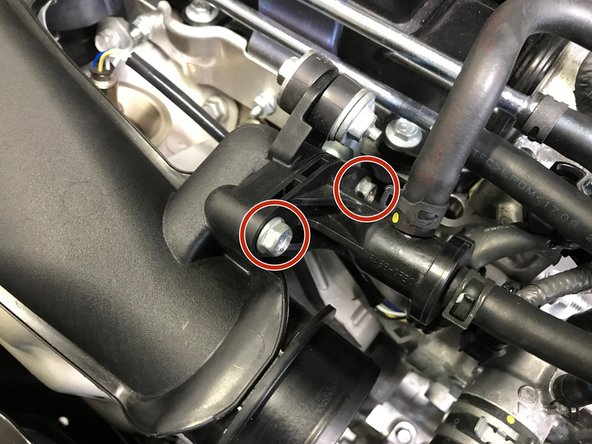

Use a 10mm socket, extension & ratchet to loosen the two (2) 10mm bolts

-

You can leave the bolts loose in position during airbox removal

-

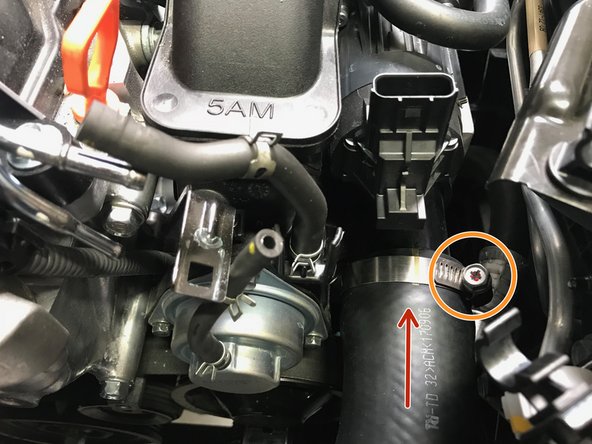

Use a 5.5mm socket to loosen the hose clamp

-

A small phillips screwdriver can be used, but is not recommend because the hose clamp head strips easily

-

-

-

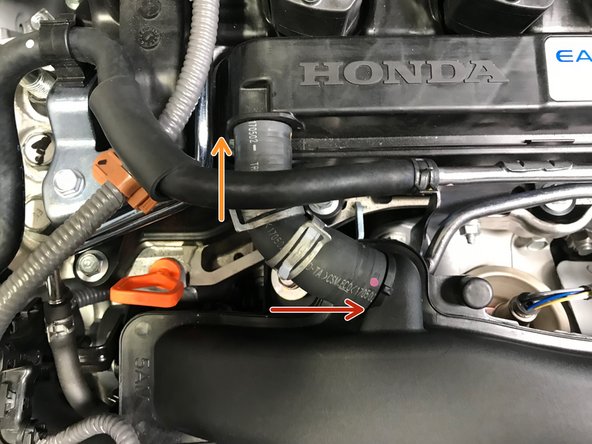

Pull the hose off the turbo inlet pipe in the direction of the arrow

-

With the hose loose, remove the entire airbox from the engine bay

-

The result will look as shown in the second image

-

-

-

Disconnect the O2 sensor wire as shown with red arrow

-

Use small pliers to remove the purple clip from the bracket

-

Pinch the back side of the purple clip and push through the bracket

-

-

-

Verify that the bracket and radiator hose are not hot. If hot allow the vehicle to cool before proceeding

-

Moving the radiator hose allows improved clearance for downpipe removal

-

Use a 10mm socket & ratchet to remove the two (2) 10mm bolts holding the lower radiator hose in place

-

With the bolts removed, move the radiator hose upward and forward

-

-

-

Apply a small amount of silicone spray to the end of the hanger rod (red arrow)

-

Use the tongue and groove pliers as shown to remove the rubber hanger

-

-

-

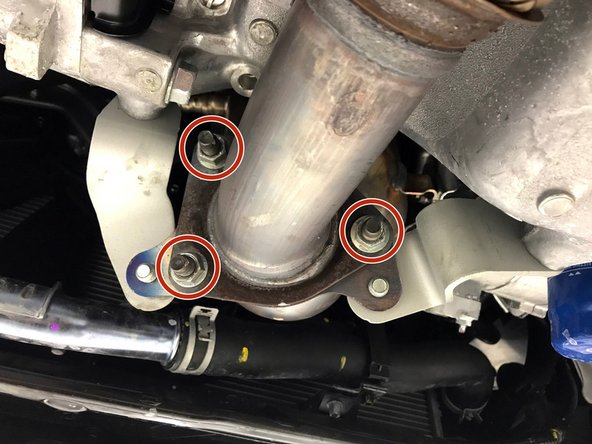

Use a 14mm socket and ratchet to remove the three OE nuts, these nuts/studs can be set aside as you will use the provided three (3) 15mm stud/nuts when reinstalling the downpipe

-

It is possible that the stud will thread out of the downpipe flange. This is not an issue. The stud can be threaded back into the flange like a bolt

-

-

-

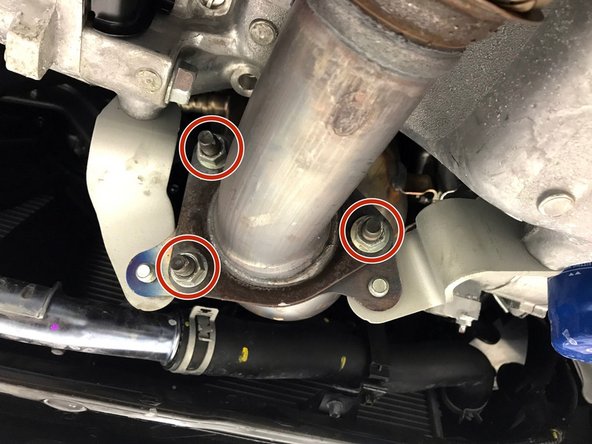

Verify that the brackets and coolant hose are not hot. If hot allow the vehicle to cool before proceeding

-

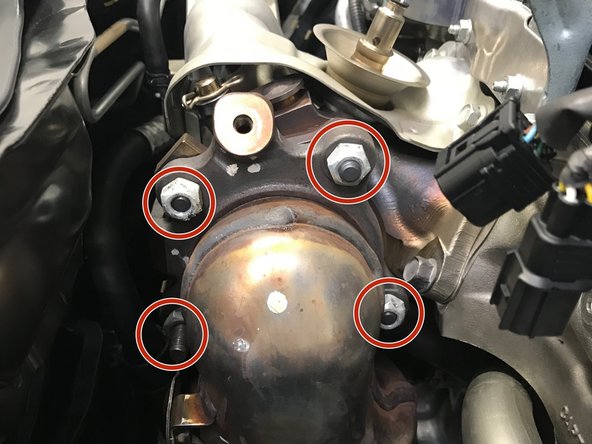

Use a 14mm socket & ratchet or wrench to remove the four (4) 14mm bolts as shown in red circles in two images

-

Remove the brackets from the vehicle

-

-

-

Locate the secondary O2 sensor on the downpipe

-

Locate the specialty socket - 22mm or 7/8" O2 sensor socket

-

Use the ratchet wrench in the specialty socket to remove the O2 sensor

-

-

-

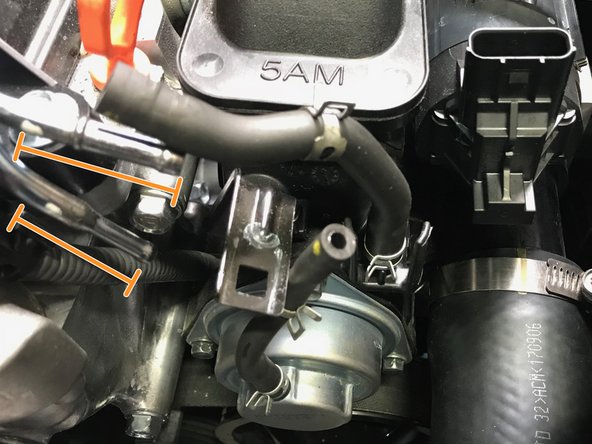

Going forward we will reference the black plastic pipe connected to the turbo as the "Turbo Inlet Pipe (TIP)"

-

The following components are identified for clarity in the following steps

-

EVAP Bleed Air

-

Valve Cover Breather Hose

-

TIP Mounting Points

-

Waste Gate Actuator (WGA) Wiring Connection

-

By-Pass Valve (BPV) Hoses

-

-

-

Use a 10mm socket & ratchet to remove the two (2) 10mm bolts

-

Pull the EVAP bleed air out of the TIP and set to the side

-

-

-

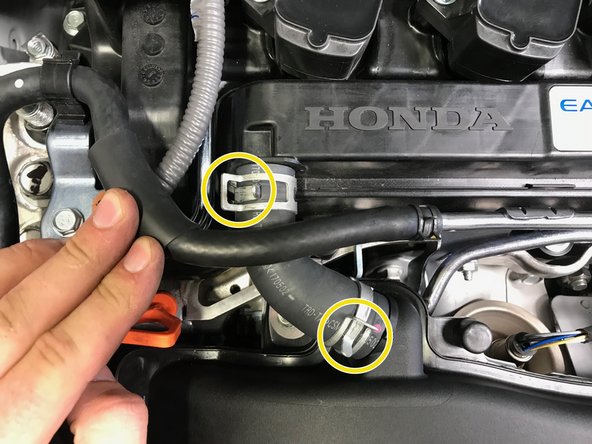

Use pliers to loosen the spring clamps. Slide the clamps towards the center of the hose

-

Pull the hose off the valve cover first

-

Pull the hose off the TIP second

-

-

-

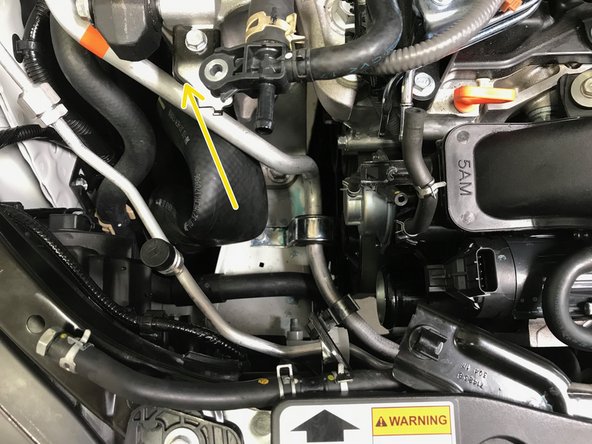

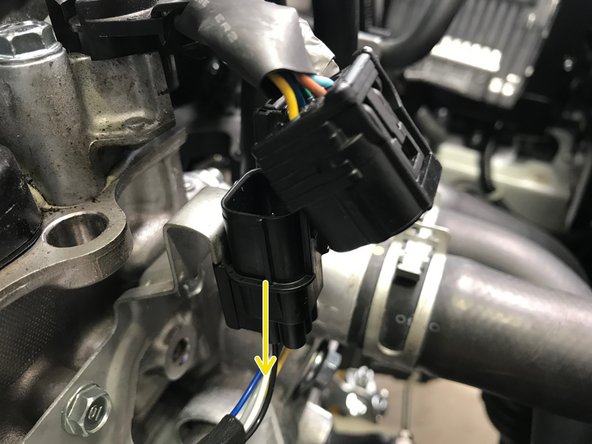

Disconnect the wiring from the Waste Gate Actuator (WGA)

-

Locate the wiring loom

-

Press down on the small tab and pull the wiring loom from the bracket in the direction of the yellow arrow

-

Move the wiring harness towards the rear of the car out of the way

-

-

-

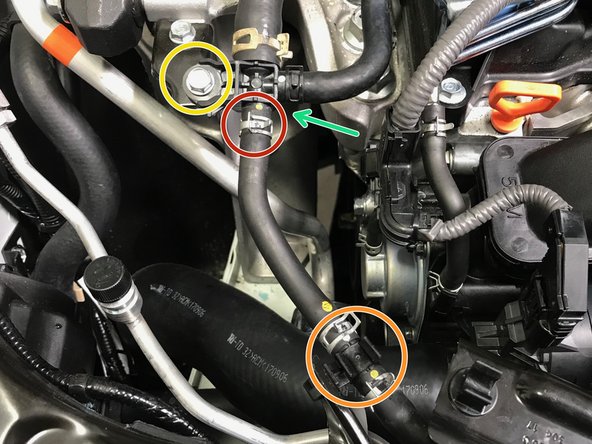

Use pliers to loosen the spring clamps. Slide the spring clamps with red circles towards the center of the hose

-

Pull the BPV hoses off the metal tubes in the direction of the orange arrows

-

-

-

Use pliers to loosen the spring clamp. Slide the clamp towards the center of the of the hose

-

Do not remove the hose yet

-

Pop the hose out of the plastic clip

-

Pull the hose off the plastic "T". Move the hose towards the front of the car out of the way

-

Some coolant may spill from the hose and "T" connection

-

Use a 10mm socket & ratchet to remove the bolt holding the "T" connection

-

-

-

Use a 10mm socket & ratchet or Phillips screwdriver to loosen the worm-gear clamp

-

Pull the hose off the TIP in the direction of the arrow

-

Remove the clamp from the hose so it does not get lost in the engine bay

-

Bend the hose towards the rear of the car. Stuff it into the fender liner out of the way

-

-

-

Use a 10mm socket & ratchet to remove the two (2) TIP mounting bolts

-

-

-

The next process is to remove the Turbo Inlet Pipe (TIP) from the vehicle.

-

We will first identify the hardware location and how to remove without losing the hardware in the engine bay

-

Second, we will show step by step images of physically removing the TIP for PDF users and a quick video for mobile users

-

-

-

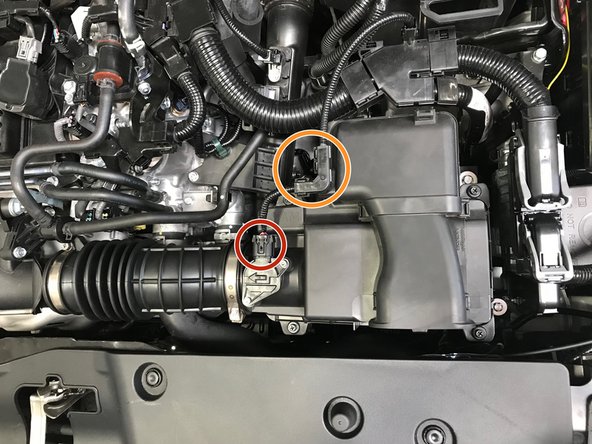

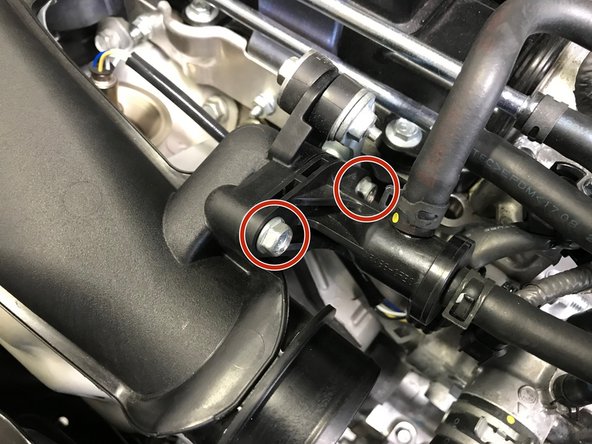

Locating the mounting hardware on the TIP can be difficult. Please see the second image for clear identification

-

The hardware circled in red are bolts. The hardware circled in orange is a nut on a stud

-

Use a 12mm socket, extension & ratchet to loosen the three (3) bolts

-

Use a 12mm socket, extension & ratchet to loosen one (1) nut

-

With the bolts loose, but not removed, use the magnet on a stick to remove the bolts from the TIP

-

-

-

Mobile Users proceed to Step 24 for video tutorial

-

Pull the oil dip stick out a couple inches and flex out of way

-

Move the TIP towards the passenger side of the vehicle past the oil dip stick

-

Reinstall the oil dip stick

-

Move the TIP further towards the passenger side of the vehicle and begin to rotate the top of the TIP towards the front of the vehicle

-

Continue the rotation of the TIP while moving the TIP up and out of the engine bay

-

-

-

Pull the oil dip stick out a couple inches and flex out of way

-

Move the TIP towards the passenger side of the vehicle past the oil dip stick

-

Reinstall the oil dip stick

-

Move the TIP further towards the passenger side of the vehicle and begin to rotate the top top of the TIP towards the front of the vehicle

-

Continue the rotation of the TIP while moving the TIP up and out of the engine bay

-

-

-

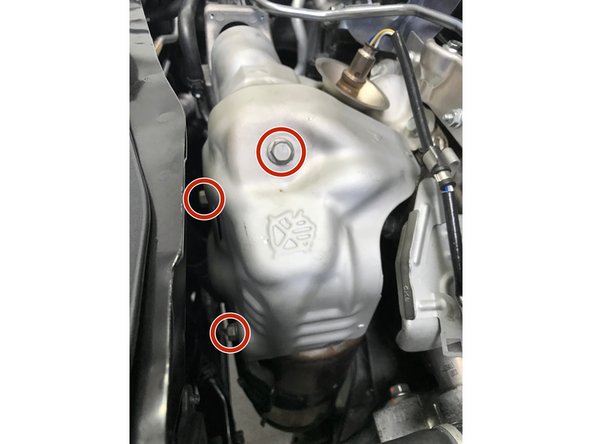

Verify that the heat shield is not hot. If hot allow the vehicle to cool before proceeding

-

Use a 12mm wrench to remove the three (3) 12mm bolts

-

Remove the heat shield from the engine bay

-

-

-

Pull the wire out of the bracket as shown with the red arrow

-

Disconnect the wiring circled in orange

-

Press a tab on the back of the wiring connection and pull down off the bracket as shown in second image

-

Move the primary O2 sensor wire to the side out of the way

-

-

-

Locate the wiring bracket to the driver's side of the turbo

-

Use a 10mm socket & ratchet to remove the two (2) 10mm bolts

-

Remove the bracket from the vehicle

-

-

-

It may be necessary to spray the studs/bolts with a penetrating lubricant before removal. Apply lubricant if needed and let sit for a few minutes then attempt removal

-

Use a 14mm socket & ratchet to remove the two (2) nuts and two (2) bolts

-

Move the downpipe off the studs towards the driver's side

-

Lower the downpipe straight down through the opening below

-

-

-

Use a 10mm socket & ratchet to remove the four (4) bolts

-

-

-

Use the specialty O2 sensor socket to install the secondary O2 sensor into the defouler. Torque to 30-33 ft-lbs

-

Locate the four (4) provided 10mm flange bolts on the downpipe

-

Use a 10mm socket and torque wrench to install the provided four (4) 10mm flange bolts and heat shield. Torque to 12-15 ft-lbs

-

-

-

In the situation that an OE stud or nut was damaged during downpipe removal, you may use a M10x1.25 stud or nut for replacement

-

Use a 14mm socket & torque wrench to install the four (4) OE studs/nuts. Torque to 42-48 ft-lbs

-

-

-

Use a 12mm wrench to install the three (3) 10mm bolts and heat shield. Torque to 15-19 ft-lbs

-

Some aftermarket downpipes may not have the provision for this heat shield

-

-

-

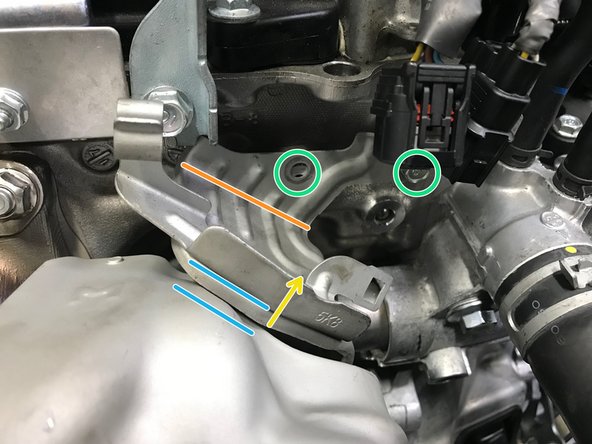

Install the bracket and hand tighten one (1) 10mm bolt into the engine shown with the red circle

-

The wiring bracket will need to be bent up slightly to clear the downpipe heat shield.

-

Bend the wiring bracket along the orange line in the direction of the yellow arrow until there is clearance

-

Clearance will require the bracket to be bent upward approximately 10mm

-

Use a 10mm socket & torque wrench to install the two (2) 10mm bolts and bracket. Torque to 8-10 ft-lbs

-

After tightening the bolts, verify there is a small clearance gap between the bracket and heat shield

-

-

-

Install the secondary O2 sensor wiring harness onto the bracket

-

Install the primary O2 sensor wiring harness onto the bracket

-

-

-

Install the primary wire into the metal clip

-

Connect the primary sensor to the wiring harness as indicated by orange arrow

-

-

-

Installation of the TIP follows the same process for removal in reverse

-

Lower the TIP into the engine bay with the TIP rotated towards the front of the car

-

Rotate and lower the TIP into the engine bay then move it towards the driver's side of the engine bay

-

Pull the oil dip stick out a couple inches and flex out of way

-

Move the TIP further to the driver's side while sliding the TIP over the stud in the compressor housing

-

Reinstall the oil dip stick

-

-

-

With the TIP loosely in position on the turbo, we will begin the most frustrating part of the entire installation.

-

Using the Magnet on a Stick we can loosely thread the nut onto the stud and the bolts into the compressor housing without the risk of losing the hardware in the engine bay

-

-

-

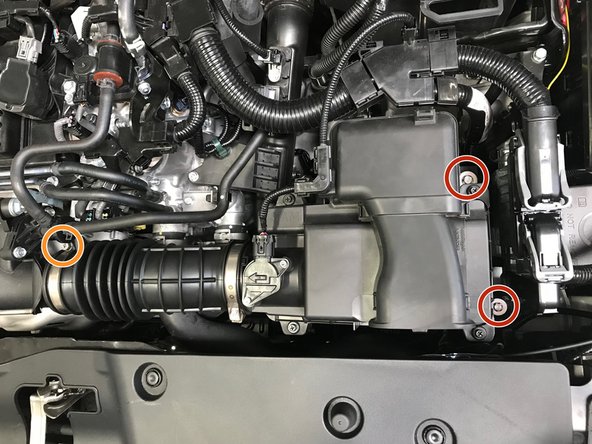

An installed TIP is shown out of the car for clarity

-

The three (3) red circles show the locations of the 12mm bolts

-

The orange circle shows the location of the 12mm nut and stud

-

Use the magnet on a stick tech tip shown in Step 37 to first loosely install the bolts and nut

-

Tighten the hardware and torque to 15-19 ft-lbs

-

-

-

Use a 10mm socket & torque wrench to install the two (2) TIP mounting bolts. Torque to 8-10 ft-lbs

-

-

-

Pull the hose out and reinstall the band clamp in the same orientation it came off

-

Push the hose onto the TIP in the direction of the arrow

-

Use a 10mm socket & ratchet or Phillips screwdriver to tighten the worm-gear clamp until snug

-

-

-

Use a 10mm socket to install the bolt holding the "T" connection. Torque to 8-10 ft-lbs

-

Pop the hose into the plastic clip

-

Push the hose onto the plastic "T". Use pliers to install the spring clamp at the end of the coolant hose around the "T" connection

-

-

-

Push the BPV hoses onto the metal tubes in the direction of the red arrows

-

Use pliers to install the spring clamps onto the end of the hoses around the metal pipe

-

-

-

Install the wiring harness back onto the bracket

-

Reconnect the wiring harness to the WGA

-

-

-

Push the hose onto the TIP first, following the red arrow.

-

Push the hose onto the valve cover second

-

Use pliers to install the spring clamps onto the end of the hose

-

-

-

Use a 10mm socket & torque wrench to install the two (2) 10mm bolts. Torque to 8-10 ft-lbs

-

-

-

Move the radiator hose back into the correct position so the bolt holes and bracket holes align

-

Use a 10mm socket & torque wrench to install the two (2) 10mm bolts holding the lower radiator hose in place. Torque to 8-10 ft-lbs

-

-

-

Use a 14mm socket or wrench to install the four (4) 14mm bolts and brackets. Torque to 38-42 ft-lbs

-

Use of the lower mounting brackets are necessary for the proper support of the downpipe

-

Failure to install these brackets can result in failure of downpipe

-

-

-

Locate the three (3) provided M10 flange nuts and the three (3) provided M10 studs

-

Use a 15mm socket & torque wrench to install the three (3) 15mm nuts/studs provided. Torque to 30-40 ft-lbs

-

Please note that the photo of the part installed on the car shows OEM hardware being used but this is not the case with current production parts.

-

-

-

Apply a small amount of silicone spray to the end of the hanger rod

-

Push the rubber hanger onto the hanger rod

-

-

-

Connect the O2 sensor to the wiring harness

-

Install the purple clip into the wiring bracket

-

-

-

Lower the airbox assembly into the engine bay

-

Install the induction hose onto the TIP

-

Use a 10mm socket and torque wrench to install the two (2) 10mm bolts that hold the airbox assembly. Torque to 3-4 ft-lbs

-

Use a 5.5mm socket or phillps screwdriver to tighten the band clamp until snug

-

Install the wiring harness into the airbox

-

Reconnect the MAF sensor wiring

-

-

-

Install the seventeen (17) plastic push-clips. Orange arrows identify the push-clips described in the next step

-

Use 10mm socket & torque wrench to install the seven (7) bolts shown in red circles. Torque to 8-10 ft-lbs

-

Use 5mm Allen and torque wrench to install the two (2) bolts shown in green circles. Torque to 8-10 ft-lbs

-

-

-

Install the remaning six (6) push-clips on each side of the skidtray

-

-

-

Defouler & Non-Catted Downpipes are strictly intended for racing use only. Installation and use are at the customers own risk

-

Some smell may be present on the first start as any residue on the downpipe burns off. This is normal and will not happen after the 1st heat cycle.

-

To get the best performance from your Performance Downpipe, we highly recommend a custom tune.

-

A custom tune for your specific vehicle with your specific modifications will provide the best performance for your Civic and the location you live in

-

-

-

This completes the installation of your 27WON Performance Downpipe

-

If you are installing a 27WON Front-Pipe along with the Downpipe, please see the Front-Pipe Instructions Here: http://store.27won.com/support/instructi...

-

We hope you were impressed with your 27WON experience and love your new Downpipe for years to come. Email us at sales@27won.com or call us at 571-271-0271 with any questions or concerns

-

Please Leave a review here: https://store.27won.com/10th-gen-civic-p...

-

Share your experience using #27WON on Instagram and Facebook

-