-

-

Poly can be removed and reinstalled in various ways. These instructions show it done with the tools we found to be the easiest

-

The Rear Motor Mount (RMM) will need to be removed from the car for this process. See our RMM install instructions for that

-

-

-

-

-

-

These options are presented in order from most preferred to least

-

Option 1: Place a 7/16” deep socket over the steel insert and use an arbor press to press the old steel insert out

-

This can also be done using a vice

-

Option 2: Use various tools

-

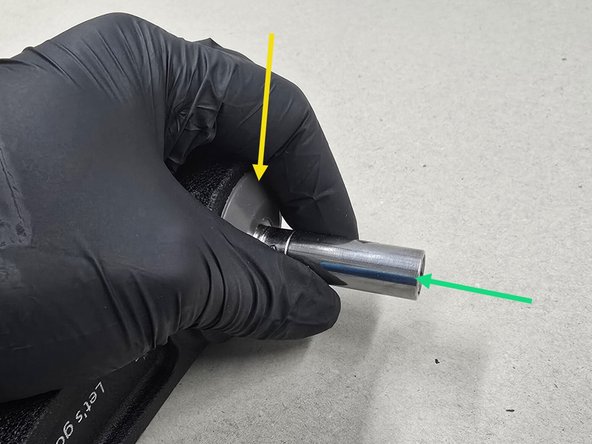

Use one hand to hold the RMM and a 7/16" deep socket as shown

-

Use a hammer or dead blow to tap the socket until the sleeve is all the way out

-

-

-

Take a 90-degree pick and insert it in the seam between the 2 poly pucks then push 1 poly puck out of the mount

-

With a flat head screwdriver, press the other piece of poly out

-

-

-

Insert the Flat poly bushing into the "Redefine" side of the RMM as shown

-

Some poly kits come with a metal washer. If this is the case then one piece of poly has a flat section the other does not. If your poly kits doesn't have a washer then both poly are the same

-

70 durometer (grey or blue) poly can be inserted by hand or with a press or vice

-

70 durometer poly comes in blue or grey. Black poly is 90 durometer

-

Flip the RMM over and insert the remaining poly into the other side as shown

-

Press the RMM down hard on a surface on each side until both pieces of poly sit flush in the mount

-

-

-

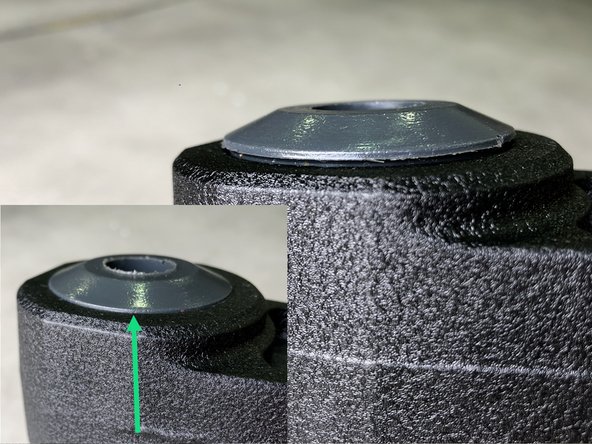

The stainless steel sleeve inserts into the RMM body in the orientation shown

-

Orient the RMM with the 'Winning is Winning" side up as shown

-

By hand insert the steel sleeve into the poly bushing as shown

-

Using an arbor press or a rubber hammer insert the steel sleeve until it is flush with the poly

-

The steel sleeve should stick out of the flat poly on the other side by about 3mm or 1/8in

-

For poly service kits without washer, the sleeve will be about flush on both poly inserts

-

-

-

You've completed installation of new RMM hardware. Reinstall the mount in the car using our installation instructions for that

-

Call us at 571-271-0271 with any questions about this process

-

Almost done!

Finish Line