Introduction

In this installation guide we have provided step by step instructions to setup, remove the OEM intake system, and install the 27WON Performance Cold Air Intake.

Advisory:

- Working under the vehicle requires a safe and sturdy location for the vehicle to sit on jackstands.

- The engine bay will be hot after recent vehicle operation. Allow the vehicle to cool or use a fan to cool the engine bay before working on the vehicle.

Tools

Parts

- L15 CAI Airbox

- Airbox Lid

- L15 CAI Long Bracket

- L15 CAI Short Bracket

- L15 CAI MAF Housing

- Silicone Coupler - MAF to TIP

- Silicone Coupler - Airbox to MAF

- Air Filter

- T-Bolt Clamp - 67-75mm × 3

- T-Bolt Clamp - 86-94mm

- T-Bolt Clamp - 108-116mm

- Standoff Rubber Isolator - M6x1.0

- SS Hex Head Screw - M5x0.8x12mm × 4

- SS Flange Button Head Screw - M5x0.8x16mm × 4

- SS Flange Nut - M6x1.0

- Rubber Dampener M6x1.0

- SS Hex Head Bolt- M6x1.0x8mm

-

-

First and foremost; THANK YOU for becoming a part of the 27WON Family. We hope to REDEFINE your experience of the aftermarket with the highest level Parts, Customer Service, Packaging, & Support

-

Aftermarket transmission coolers may not fit with our intake

-

-

-

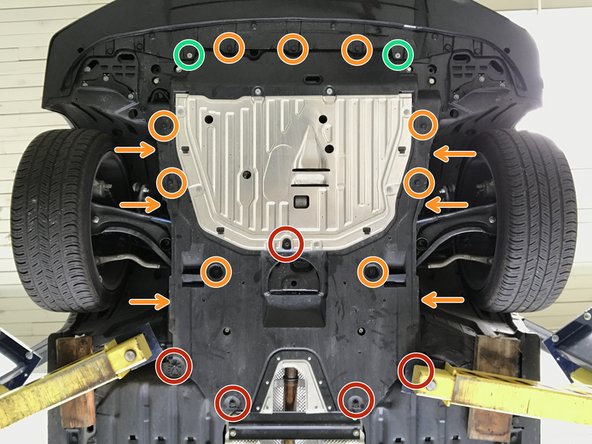

Locate the engine under tray to gain access to the OE lower airbox

-

Use 5mm Allen Key to remove the two (2) bolts shown in green circles

-

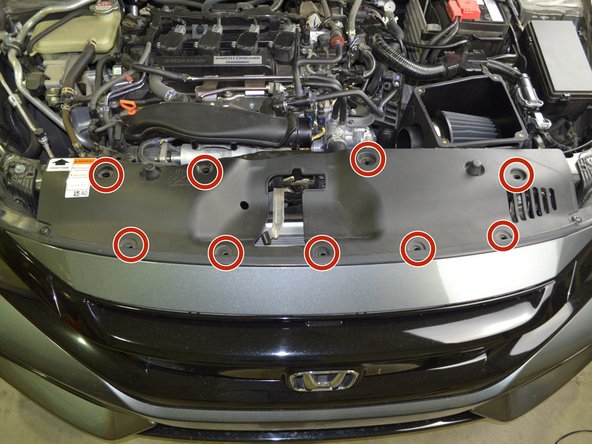

Use 10mm socket & ratchet to remove the seven (7) bolts shown in red circles

-

Use a flathead screwdriver to remove the seventeen (17) plastic push-clips. Orange arrows identify the push-clips in described in the next step (3)

-

-

-

Use large flat head screw driver to remove push-clips on each side of skidtray

-

-

-

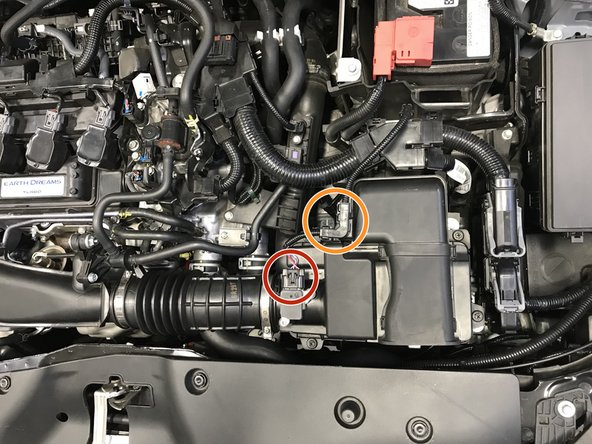

Disconnect the wiring harness from the MAF Sensor

-

Remove the wire cover from the airbox

-

Use needle noise pliers to pinch the clips then pull the cover off the airbox

-

-

-

The MAF wire cover consist of two halves that are held together by push lock clips. These will need to be unlocked to remove the cover

-

Step 6 will show how to pull apart MAF wire cover

-

-

-

Using small flathead screwdriver, gently pry between the square loop and the prong, then pry the prong out of the loop

-

It takes very little force to insert the flathead screwdriver and pry loose, try not to break the square loop

-

With all four prongs unlocked the cover should open as shown

-

Pull the wire out of the cover and wrap the exposed section in electrical tape

-

-

-

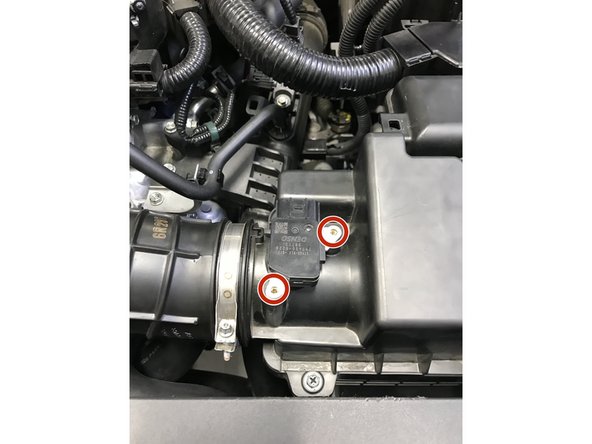

Use a small Phillips screwdriver to remove the two screws

-

Remove the MAF sensor from the airbox and reinstall the OE screws into the airbox, they are not used in the 27WON CAI

-

Base Model MAF Sensor shown, SI MAF Sensor removal is same

-

-

-

Use a 5.5mm socket to loosen the hose clamp

-

A small phillips screwdriver can be used, but is not recommend because the hose clamp head strips easily

-

-

-

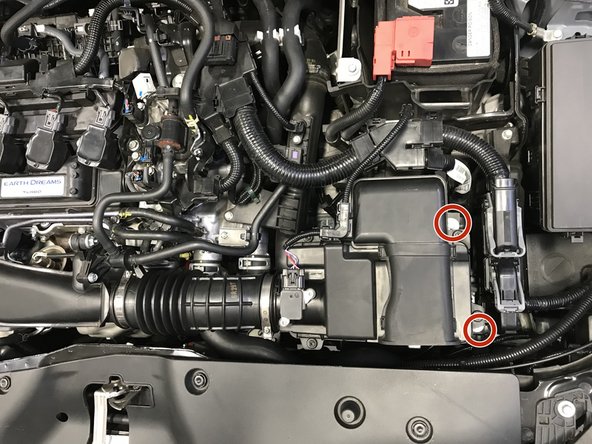

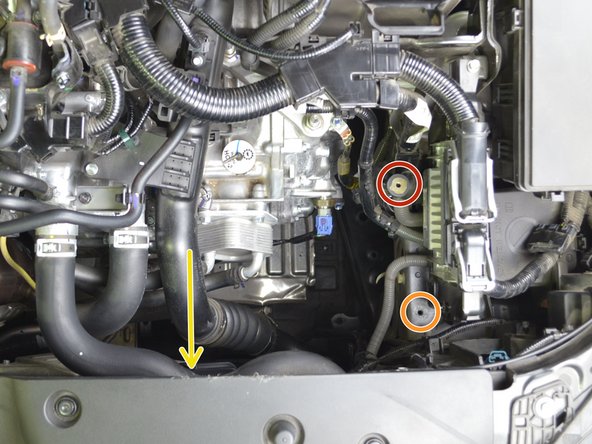

Use a 10mm socket and long extension to unthread the two silver mounting bolts

-

You can leave the bolts loose in position during airbox removal

-

-

-

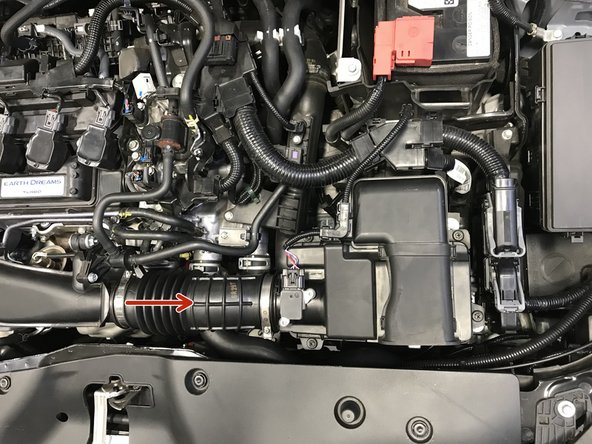

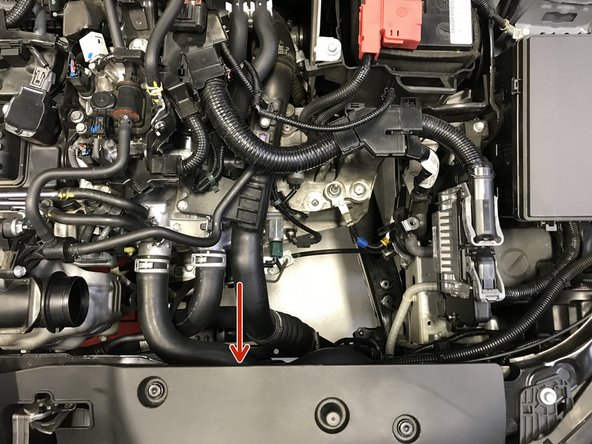

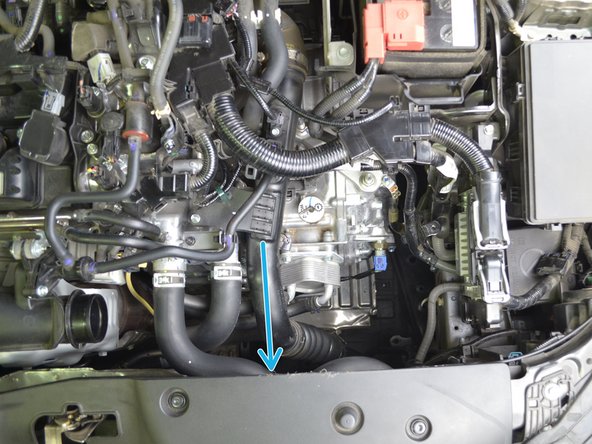

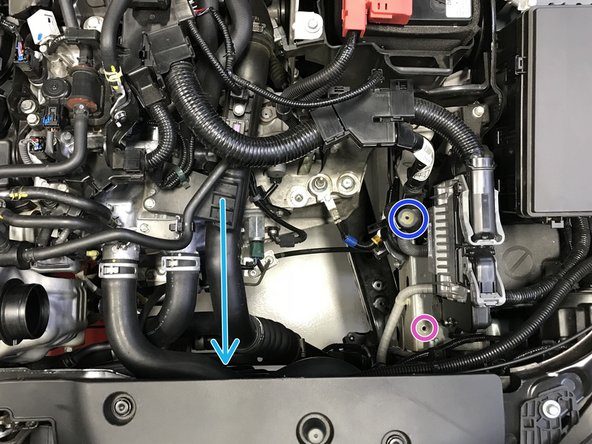

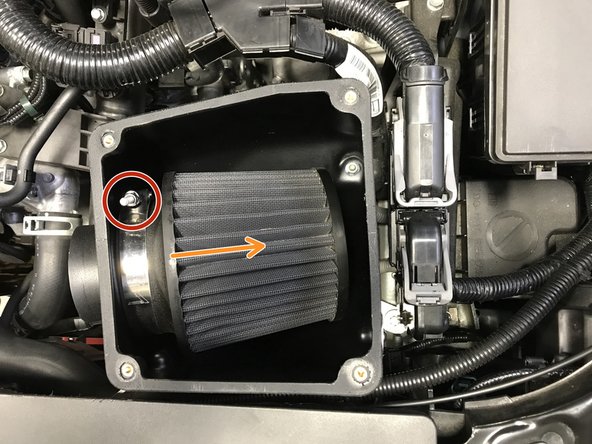

Pull the hose off the turbo inlet pipe in the direction of the arrow

-

With the hose loose, remove the entire airbox from the engine bay

-

The result will look as shown in the second image

-

-

-

From under the vehicle locate the two bolts, use a 10mm socket & ratchet to remove the two bolts

-

Remove the lower airbox assembly from the vehicle

-

The result will look as shown in the second image

-

-

-

From under the vehicle, locate lower airbox assembly mounting bracket

-

Use a 10mm socket & ratchet to remove the bolt

-

Remove the bracket from the vehicle

-

-

-

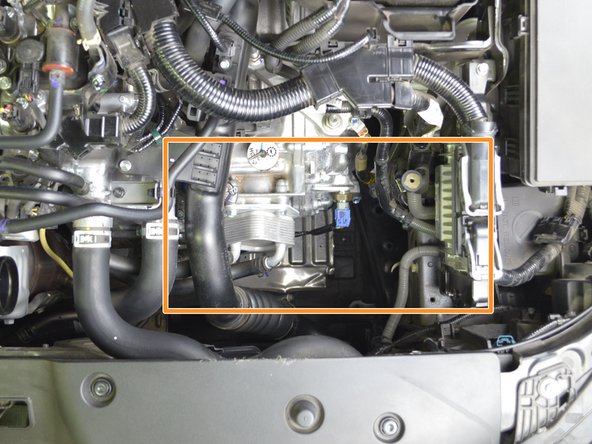

The red square shows where the lower inlet of the airbox will sit in the engine bay and fender well

-

-

-

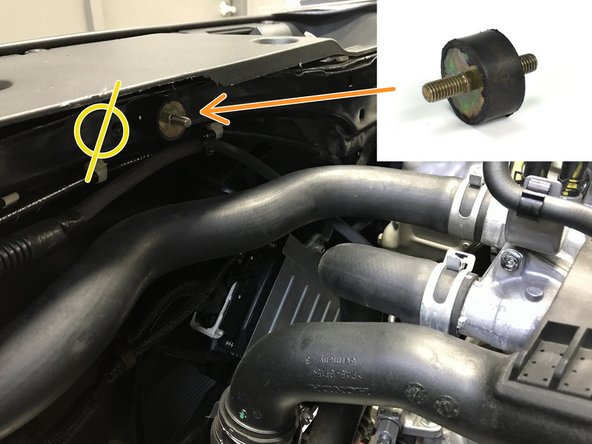

Locate the provided rubber isolator standoff for step 15

-

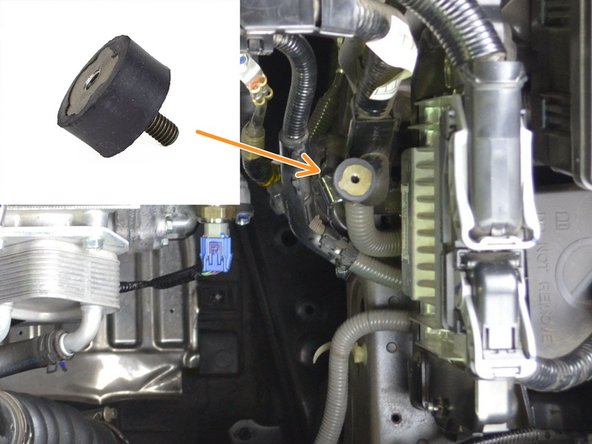

Locate the provided rubber dampener for step 16

-

-

-

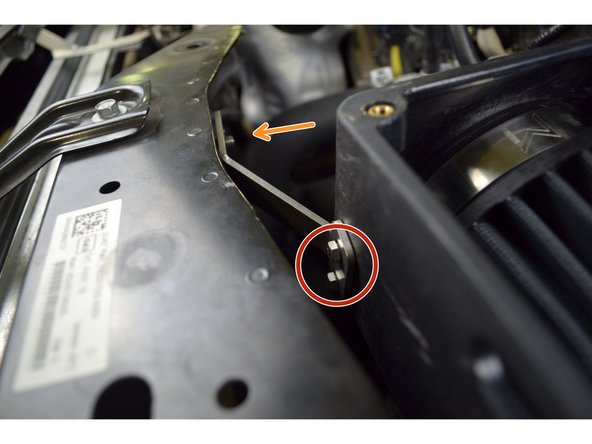

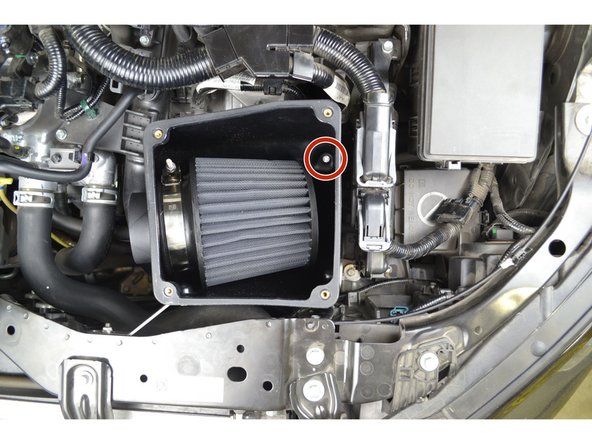

Locate threaded hole in the core support for manual transmissions

-

Locate threaded hole in the core support for Automatic transmissions

-

Install the rubber isolator standoff in the threaded hole closest to the turbocharger. Tighten hand tight using your fingers

-

There are two threaded holes located in the core support, use the hole closest to the turbocharger. Don't use the hole marked in yellow

-

-

-

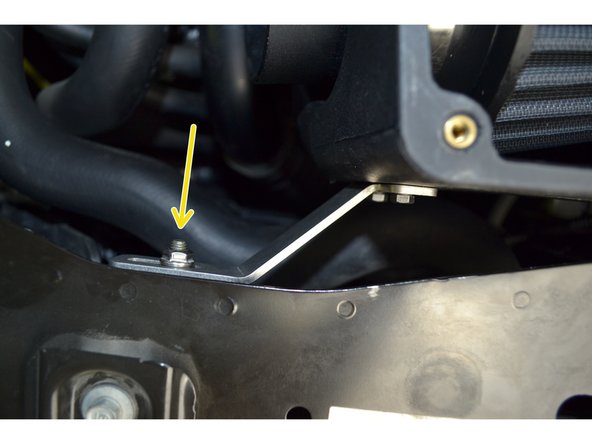

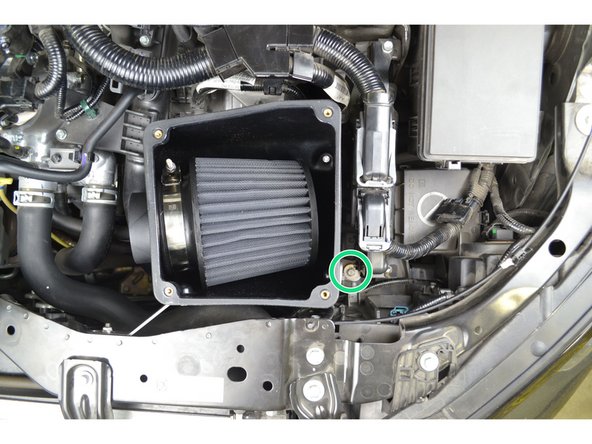

Locate threaded hole in the bracket for manual transmissions

-

Locate threaded hole in the bracket for Automatic transmissions

-

Install the rubber dampener in the threaded hole found in the bracket, tight hand tight with fingers

-

The bracket is mounted to the chassis rail next to the ECU

-

-

-

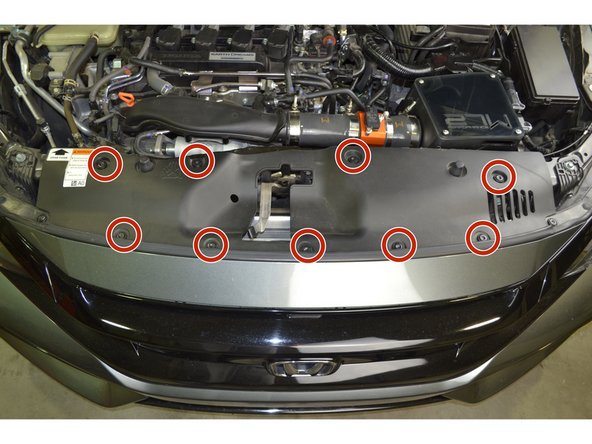

Carefully pry the 9 plastic clips open with a flat head screw driver

-

Clips are fragile and can easily break if to much force is applied

-

-

-

Locate the OE Airbox Assembly

-

Identify one of the OE rubber mounts and remove the OE bolt (the bolt should be loose in the mount)

-

Keep this bolt, it will be used later

-

Press the metal collar out of the rubber mount with your hands.

-

Pinch the rubber mount together then remove the rubber mount from the OE airbox assembly

-

-

-

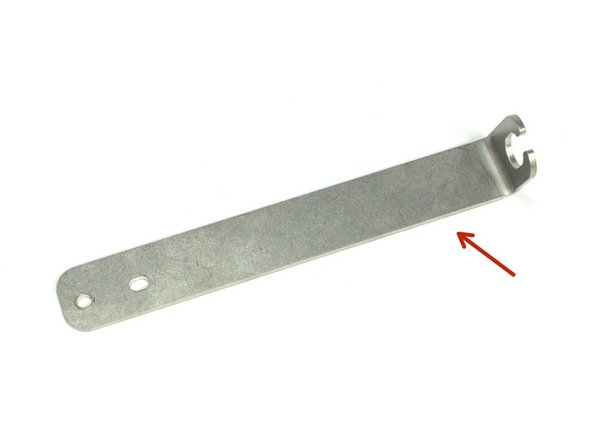

Locate the Long Bracket

-

Locate the Short Bracket

-

Locate QTY=4 M5x0.8x12mm Hex Head Bolts

-

-

-

Install the OE rubber mount and steel collar as shown

-

-

-

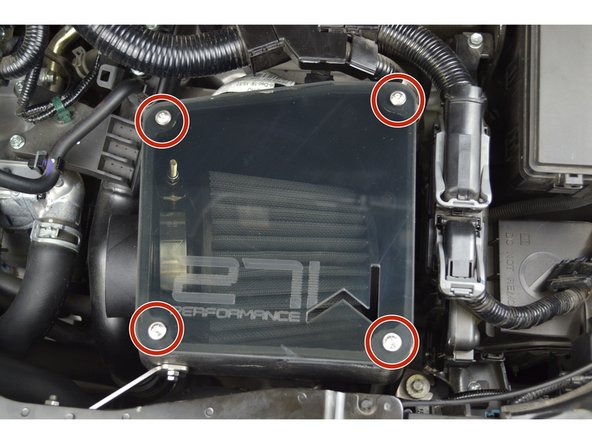

Use a 3mm Allen Key to remove the four flanged button head bolts holding the lid on

-

Remove the protective cover on the lid and set the lid aside on a non-abrasive surface

-

Unwanted scratches could occur if lid is not handled with care

-

With the lid removed you now have access to the air filter and the inner airbox mounting location

-

-

-

Using a 8mm socket and ratchet, install the bracket as shown

-

Torque bolts to 24-48 in-lbs

-

-

-

Locate the OE airbox mounting bolt

-

Locate the provided QTY=1 M6x1.0 Flange Nut

-

Locate the provided QTY=1 M6x1.0 Hex Head Bolt

-

-

-

This Clearance warning applies to vehicles with automatic transmissions. Skip step if vehicle has a manual transmission.

-

Inside the orange box there are multiple tight clearances due to the CVT.

-

Be careful not to run into this sensor. The airbox will clear the sensor but carelessness when inserting the box could damage the sensor

-

The bottom of the airbox fits right into this square opening

-

In some cars, airbox may touch this sensor. It is ok. Give us a call if this concerns you

-

Be careful not to run into the transmission cooler. The airbox will clear the cooler but carelessness when inserting the airbox could damage the airbox

-

Aftermarket transmission coolers may not fit with our intake

-

-

-

Before positioning the 27WON airbox into the engine bay, please identify the correct mounting locations

-

Manual transmission inner airbox mounting point

-

Manual transmission long bracket mounting point

-

Manual transmission short bracket mounting point

-

Automatic transmission inner airbox mounting point

-

Automatic transmission long bracket mounting point

-

Automatic transmission short bracket mounting point

-

-

-

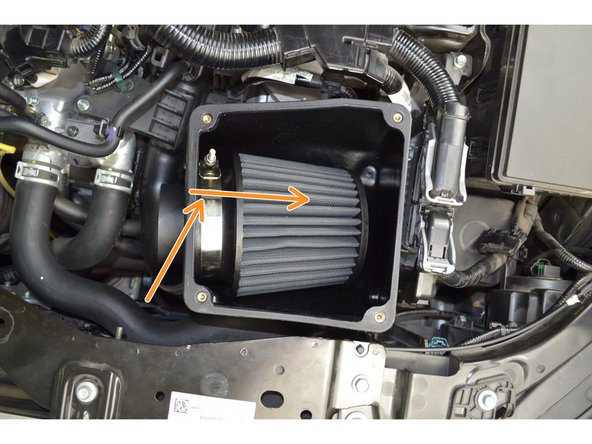

Lower the 27WON airbox into the engine in the orientation shown.

-

Swivel the airbox into position

-

-

-

Now that the airbox is in position. Attach the provided short bracket to the airbox with (2) M5x0.8X12mm hex head bolts and a 8mm wrench

-

Aline the slotted end of the short bracket onto the rubber isolator

-

Thread the provided M6x1.0 flange nut onto the rubber isolator. The nut should be loose enough to allow the airbox to still slide within the slotted hole

-

-

-

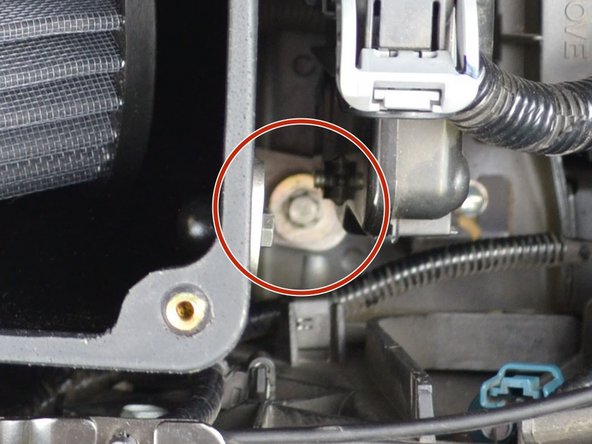

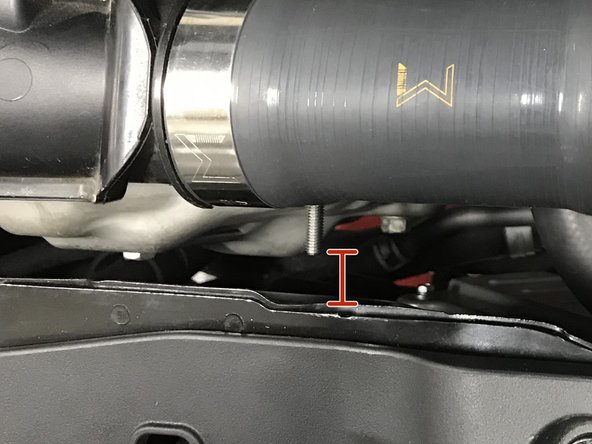

Aline the inner hole with the hole in the rubber dampener and insert the provided hex head M6x8mm bolt. Tighten using a 10mm socket with an extension and a ratchet

-

Tighten the bolt to 12-24 in-lbs

-

Do not over tighten the bolt. This could damage the airbox.

-

-

-

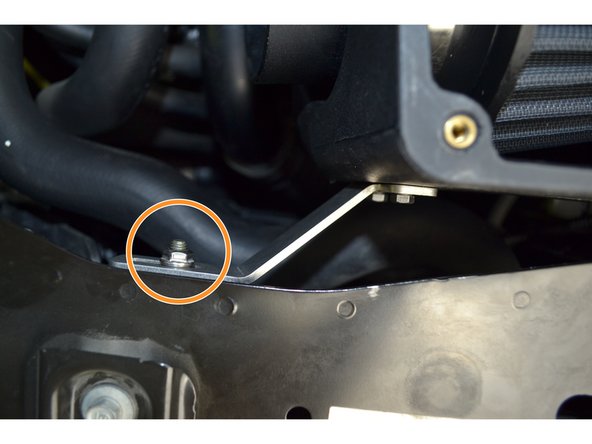

Aline on the Long bracket with the threaded hole in the chassis

-

Insert the OE bolt into the long bracket

-

Tighten with a 10mm socket with extension and ratchet, Torque the OE bolt in the long bracket to 36-48 in-lbs

-

-

-

Tighten the M6x1.0 flange nut on the rubber isolator using a 10mm socket and ratchet to 24-36 in-lbs

-

-

-

Place the airbox lid onto the airbox

-

Install the four M5x0.5x16mm flanged button head bolts, Tighten the bolts to 12 in-lbs

-

The lid can crack if significantly over-tightened.

-

If the holes in the lid do not want to align exactly with the threaded inserts, you can lightly twist/push the airbox. The mounting process can distort the shape of the bow slightly. This is nothing to worry about

-

-

-

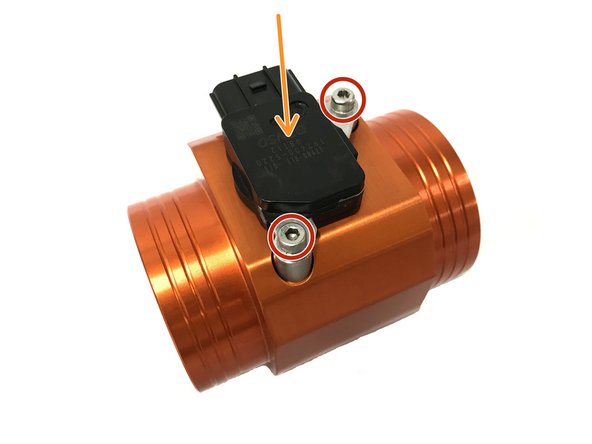

The MAF housing comes assembled with the necessary MAF sensor installation hardware

-

The MAF housing has a small cutout at the top for the wiring harness. This cutout will face the rear of the vehicle once installed

-

Silicone coupler between the MAF housing and the OE turbo inlet pipe

-

Silicone coupler between the MAF housing and the airbox

-

On both silicone couplers there is a "W" logo. The bottom of the "W" will face the front of the vehicle once installed

-

-

-

Use a 3mm Allen Key to remove the socket cap bolts from the MAF housing

-

Install the MAF sensor into the housing

-

If you are having issues, push the sensor into the housing while turning the sensor, this should help

-

Be careful to not pinch and damage the o-ring on the sensor

-

Align the sensor with the stainless steel standoff and install the socket cap bolts

-

Torque the socket cap bolts to 24-48 in-lbs

-

-

-

Locate the provided QTY=1 67-75mm clamps.

-

Locate the provided QTY=1 86-94mm clamp

-

The 108-116mm clamp is already installed on the air filter

-

-

-

Verify that your MAF & Silicone Assembly has came as shown

-

Install the 67-75mm clamp loose as shown

-

Install the 86-94mm clamp loose as shown

-

A small gap between the end of the silicone and the MAF housing is normal. This is required for proper connection of the internal step in the silicone

-

-

-

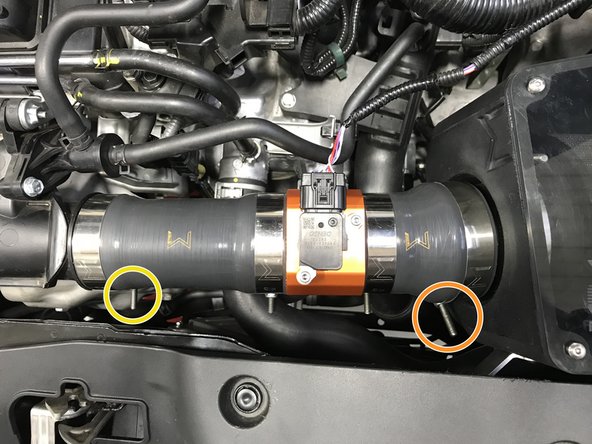

Angle the MAF & Silicone assembly into the engine bay and onto the airbox

-

Verify the silicone coupler connecting to the airbox is over the circumference of the airbox outlet

-

-

-

Pivot the MAF & Silicone assembly down and onto the turbo inlet pipe

-

The silicone coupler is flexible enough to bend and distort as needed to fit over the turbo inlet pipe

-

Adjust the silicone coupler to fit around the entrance of the turbo inlet pipe

-

-

-

If needed, rotate the MAF & Silicone assembly so the MAF sensor and "W" are facing upward as shown

-

Use a 10mm wrench or socket and wrench to tighten the 86-94mm clamp on the airbox

-

Use a 10mm wrench or socket and wrench to tighten the 67-75mm clamp on the turbo inlet pipe

-

Tighten the clamps until snug (the silicone will start to bulge at the edge of the clamp slightly)

-

-

-

Connect the wiring harness to the MAF sensor as shown

-

Check clearance of the clamp at the turbo inlet pipe, verify there is approximately 3/4" clearance from the end of the T-bolt rod to the core support. Rotate clamp to adjust if necessary

-

-

-

Reinstall radiator fan guard by inserting the 9 plastic clips and pressing down on them with your thumb

-

-

-

Re-install the 10mm bolts with a 10mm socket & torque wrench. Torque to 8-12 ft-lbs

-

Re-install the 5mm socket flange bolts with the 5mm Allen key & torque wrench. Torque to 6-8 ft-lbs

-

Re-install the push clips at the bottom of the undertray and the sides (shown in Step 2)

-

-

-

Re-install the push clips at the side of the undertray

-

-

-

This completes the installation of your 27WON Performance Cold Air Intake System.

-

We hope you were impressed with your 27WON experience and love your new Cold Air Intake for years to come. Email us at sales@27won.com or call us at 571-271-0271 with any questions or concerns

-

We recommend going to the next step to learn how to service the air filter or check our video on cleaning the air filter at https://youtu.be/nE7diTeI4Gw

-

Please Leave a review here: https://store.27won.com/10th-gen-civic-c...

-

Share your experience using #27WON on Instagram and Facebook

-

-

-

The next step explains how to remove and reinstall your air filter for cleaning and service.

-

When re-installing your air filter be careful not to compress the velocity stack on the air box to a point of deformation. Doing so can cause the air box to crack and the air filter to fall off

-

-

-

Here we show how to remove the air filter for standard maintenence

-

Use a 3mm Allen Key to remove the four bolts, then remove the airbox lid

-

Use a 10mm socket and wrench to loosen the clamp

-

Pull the air filter off the airbox velocity stack then pull the filter straight up and out of the airbox

-

The air filter is a tight squeeze to remove, do not worry if the airbox or air filter flex or distorts slightly

-

Reinstall the air filter in the reverse order.

-

Hold the air filter tight against the airbox velocity stack and tighten the clamp snug. Verify the air filter cannot be pulled loose with a gentle tug

-

Verify that the T-bolt rod is not protruded past the top of the airbox, this would damage the airbox lid

-