Introduction

In this installation guide we have provided step by step instructions to setup, remove the OEM exhaust, and install the 27WON Performance Exhaust.

Advisory:

- Working under the vehicle requires a safe and sturdy location for the vehicle to sit on jackstands.

- The exhaust piping will be hot after recent vehicle operation. Allow the vehicle to cool or use a fan to cool the exhaust piping before working on the vehicle.

Tools

-

-

First and foremost; THANK YOU for becoming a part of the 27WON Family. We hope to REDEFINE your experience of the aftermarket with the highest level Parts, Customer Service, Packaging, & Support

-

-

-

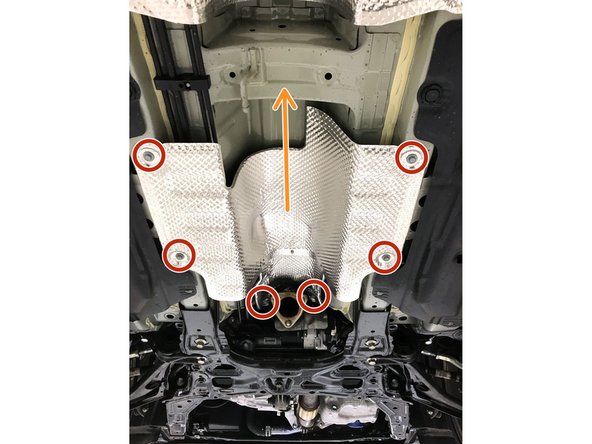

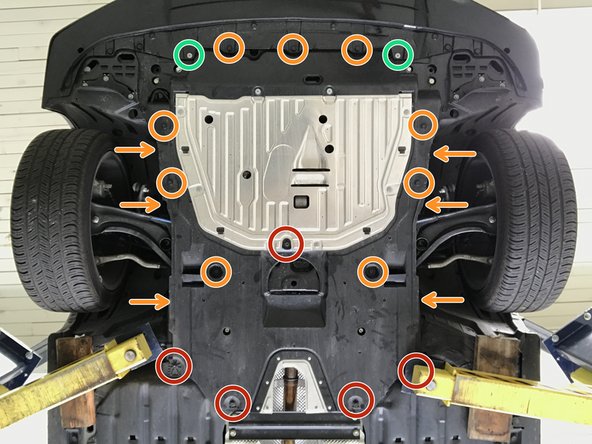

Locate the engine under tray to gain access to the connection between the front-pipe and down stream exhaust

-

Use 5mm Allen Key to remove the two (2) bolts shown in green circles

-

Use 10mm socket & ratchet to remove the five (5) bolts shown in red circles

-

Use a flathead screwdriver to remove the fifteen (15) plastic push-clips. Orange arrows & circles identify push-clips in Step 3

-

Yellow square identifies cross-member in Step 6

-

The bracket highlighted in yellow is not found on SI models

-

-

-

Use large flat head screw driver to remove push-clips on each side of undertray

-

-

-

Use 14mm socket & ratchet to remove the 4 bolts holding the cross member

-

This bracket is not found on the SI models

-

-

-

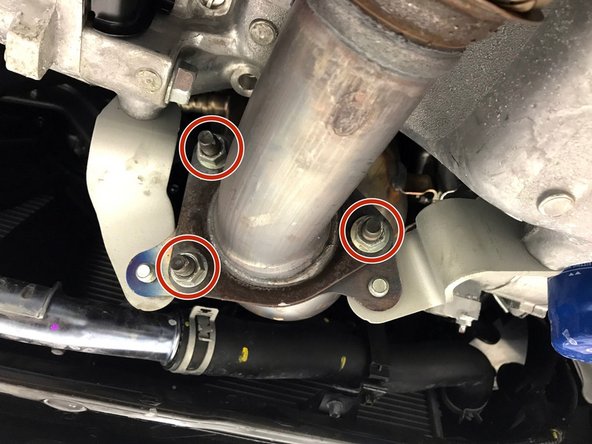

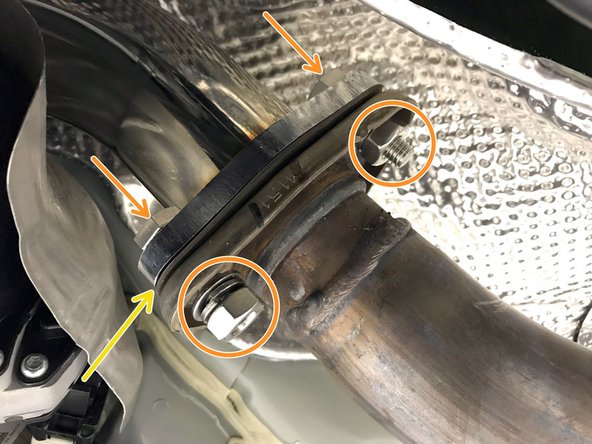

Locate the connection between the front-pipe and down stream exhaust

-

Verify that the exhaust is not to hot to touch, if still hot use a fan to cool the exhaust piping before proceeding

-

Use 14mm socket & ratchet to remove three (3) OE nuts in red circles, as shown

-

-

-

Front-pipe back exhaust has been removed for clarity of image, but doe snot need to be removed to relocate the heat shield out of the way

-

Use a 10mm socket and ratchet to remove the six bolts holding the heat shield

-

Relocate the heat shield in the direction of the arrow

-

With front-pipe back exhaust installed; Set the heat shield on the pipe. You only need to provide clearance around the flange

-

With front-pipe back exhaust removed; Remove the heat shield from the vehicle

-

-

-

Apply a small amount of silicone spray to the end of the hanger rod

-

Use the tongue and groove pliers as shown to remove the rubber hanger

-

-

-

Use a 14mm socket and ratchet to remove the three OE nuts

-

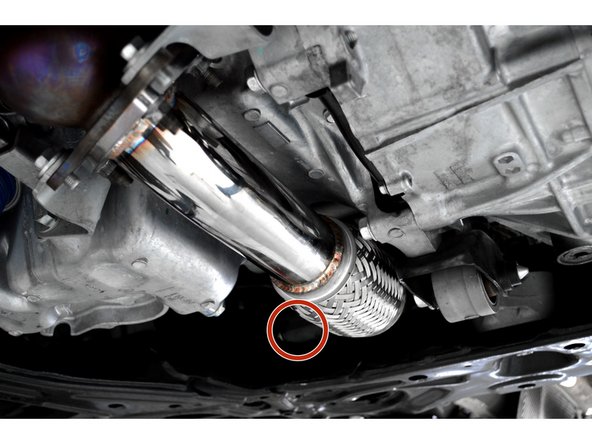

It is possible that the stud will thread out of the downpipe flange. This is not an issue, the stud can be threaded back into the flange like a bolt

-

-

-

Remove the OE front-pipe from the vehicle through the access point directly under the engine

-

-

-

Locate the provided "house" gasket for front-pipe installation

-

-

-

Install the provide "house" gasket between the flanges

-

Align the studs through the flange then hand tighten the nuts

-

Use a 14mm socket & torque wrench to torque each to 30-40 ft-lbs

-

-

-

Reinstall the OE rubber hanger

-

Reinstall the OE heat shield with the bolts hand tight

-

Use 10mm socket & toque wrench to torque to 6-8 ft-lbs

-

-

-

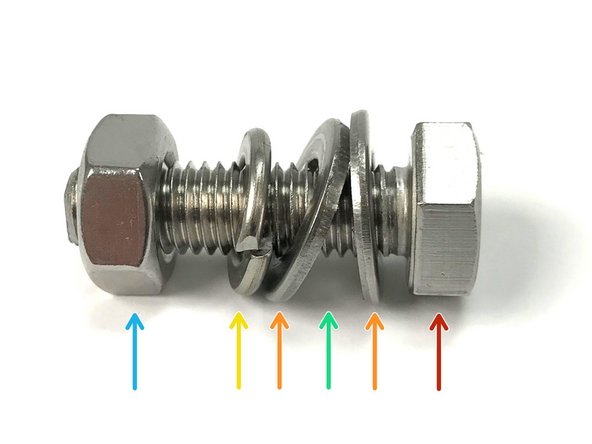

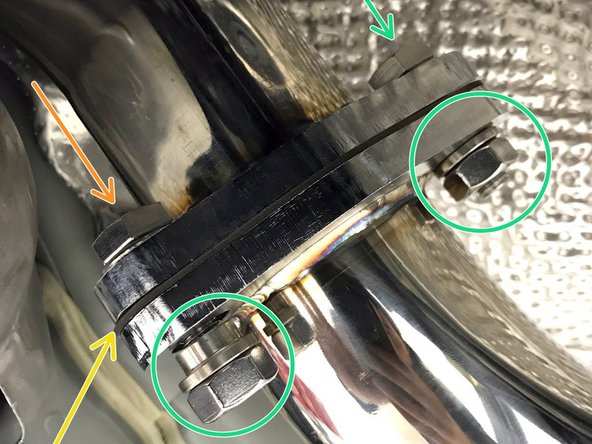

The location of the flat washers, flanges, and split lock washer are critical for proper fastening and vibration resistance.

-

17mm M10 Nut

-

M10 Split Lock Washer

-

M10 Flat Washers

-

Exhaust Pipe Flange Location - Between the two flat washers

-

17mm M10 Bolt Head

-

-

-

Locate the provided "tri-bolt" gasket for front-pipe installation

-

Locate QTY=3 provided 35mm length assembled M10 bolts

-

Locate QTY=3 provided step nuts

-

-

-

For your assistance in installing the 27WON Front-Pipe, we have laid out the installation with the 27WON Front-Pipe Back Exhaust and OE Front-Pipe Back Exhaust

-

Step 16 Show the installation with the 27WON Front-Pipe Back Exhaust

-

Step 17 Show the installation with the OE Front-Pipe Back Exhaust

-

-

-

If you are connecting to the OE front-pipe back exhaust, skip to Step 17

-

Install the provide tri-bolt metal gasket

-

Using the 35mm length M10 bolts, insert the bolts through the front-pipe flange first

-

Install the provided step washers and nuts as shown

-

When using the step washer, DO NOT use the flat washer and split lock washer

-

It is important that the provided step nuts are used with the 27WON Front-Pipe Back Exhaust to properly align the flanges

-

While hand tightening the nuts, verify that the step washers inserting into the flange correctly. Use a 17mm socket & torque wrench to torque the bolts to 30-40 ft-lbs

-

-

-

If you have already connect your Front-Pipe to the 27WON Exhaust then you can skip this step

-

Install the provided metal gasket

-

Using the 35mm length M10 bolts, insert the bolts through the front-pipe flange first

-

See Step 13 for hardware setup

-

Install the remaining washers and nuts. Use a 17mm socket & torque wrench to torque the bolts to 30-40 ft-lbs

-

-

-

Start the vehicle to check for leaks or rattles. If none, then take a spin around the block for further verification. If you do find a leak or rattle, please inspect the exhaust further

-

A leak could be caused by a loose flange bolt, improperly used gasket, or if debris is stuck between the gasket and flange

-

A rattle could be caused by misaligned pipe or a rubber hanger being orientated incorrectly

-

If you have exhausted all investigation then give us a call and we would be happy to help and resolve the issue with you

-

-

-

Re-install the 10mm bolts with a 10mm socket & torque wrench. Torque to 8-12 ft-lbs

-

Re-install the 5mm socket flange bolts with the 5mm Allen key & torque wrench. Torque to 6-8 ft-lbs

-

Re-install the push clips at the bottom of the undertray and the sides (shown in Step 20)

-

-

-

Re-install the push clips at the side of the undertray

-

-

-

Re-install the cross member. Use a 14mm socket & torque wrench to torque the bolts to 25-35 ft-lbs

-

The bracket highlighted in yellow is not found on SI models

-

-

-

This completes the installation of your 27WON Performance Exhaust

-

We hope you were impressed with your 27WON experience and love your new exhaust for years to come. Email us at sales@27won.com or call us at 571-271-0271 with any questions or concerns

-

Please Leave a review here: https://store.27won.com/civic-hatchback-...

-

Share your experience using #27WON on Instagram and Facebook

-