Introduction

In this installation guide we have provided step by step instructions to remove the OEM boost tubes and install the 27WON Performance Boost Tubes.

Advisory:

- Working under the vehicle requires a safe and sturdy location for the vehicle to sit on jackstands.

- The engine bay will be hot after recent vehicle operation. Allow the vehicle to cool or use a fan to cool the engine bay before working on the vehicle.

Tools

-

-

First and foremost; THANK YOU for becoming a part of the 27WON Family. We hope to REDEFINE your experience of the aftermarket with the highest level Parts, Customer Service, Packaging, & Support

-

The 27WON Boost Tubes are designed with OEM like fitment and closely match overall size and routing. However, fitment with non-27WON aftermarket intakes and intercooler kits is not guaranteed

-

This is shown on an FL5 Type R. The process is identical on the Integra Type S

-

-

-

Raise the vehicle and support with jackstands in the OE recommended locations

-

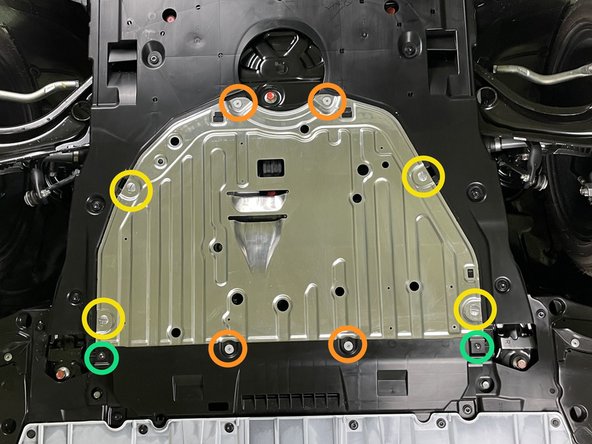

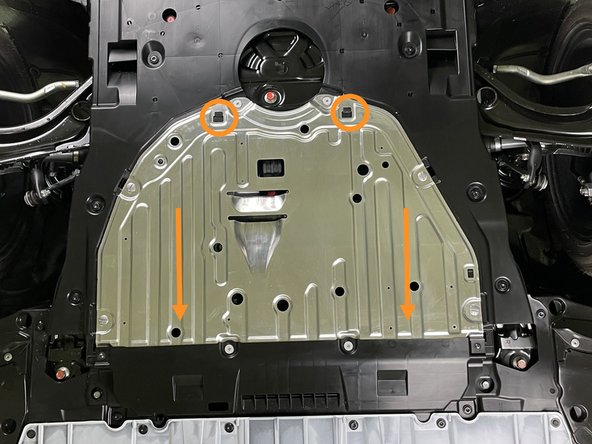

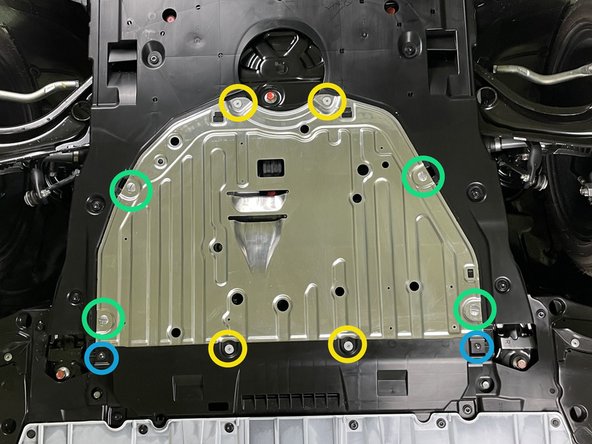

Locate the engine undertray to gain access to the OEM hot side boost tube and lower section of the OEM cold side boost tube

-

Remove the four Phillips head bolts using a Phillips screwdriver

-

Remove the four quarter turn screws using a large Flathead screwdriver

-

Remove the two Philips head screws using a Philips screwdriver

-

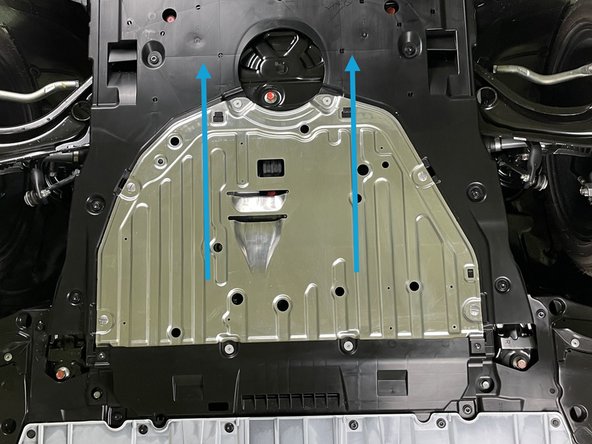

Slide the metal section rearward and remove it from the vehicle

-

The metal section of the undertray can be sharp. Use caution when handling it

-

-

-

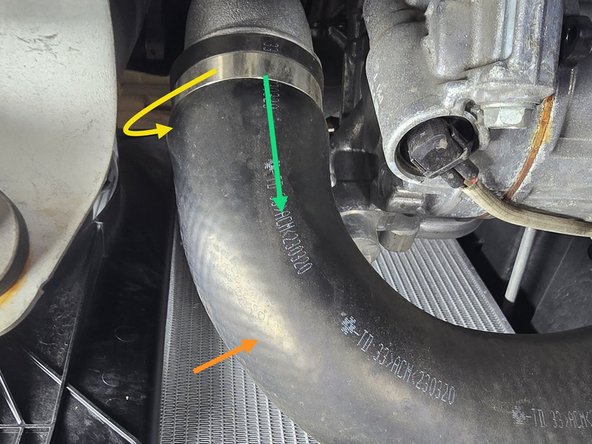

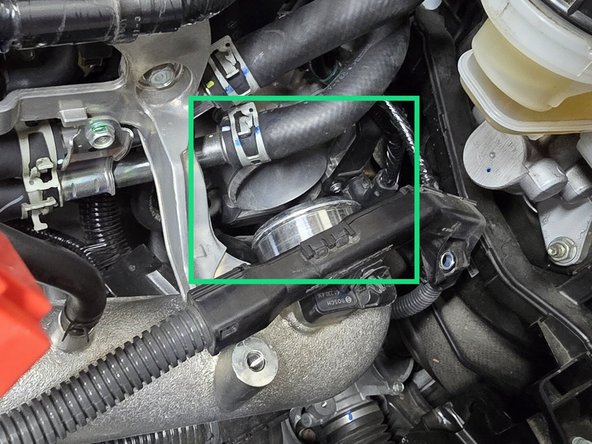

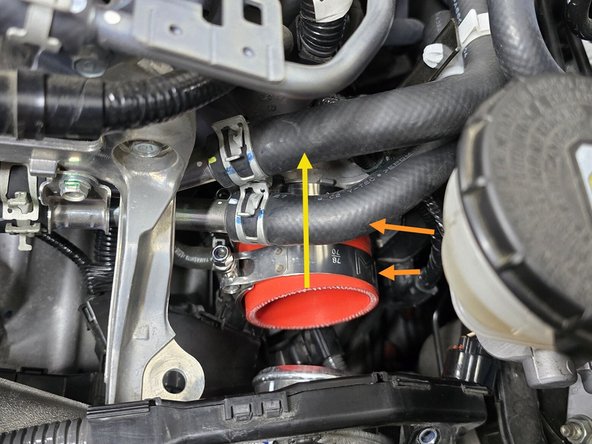

Locate the OEM hot side boost tube. It's in the general area of the orange arrow

-

Loosen the clamp that connects the OEM hot side boost tube to the turbocharger using a 10mm socket and a 3/8" drive ratchet

-

Slide the clamp toward the center of the OEM hot side boost tube and out of the way

-

-

-

Loosen the clamp that attaches the OEM hot side boost tube to the intercooler using a 10mm socket and ratchet

-

Slide this clamp toward the center of the OEM boost tube and out of the way

-

Pull the OEM boost tube free from the turbocharger

-

Pull the OEM boost tube free from the intercooler and remove it from the vehicle

-

-

-

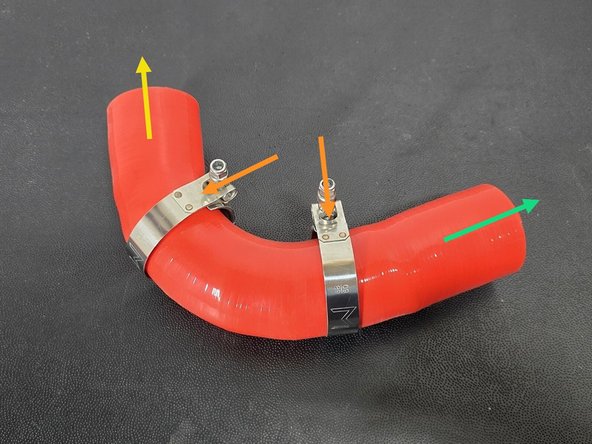

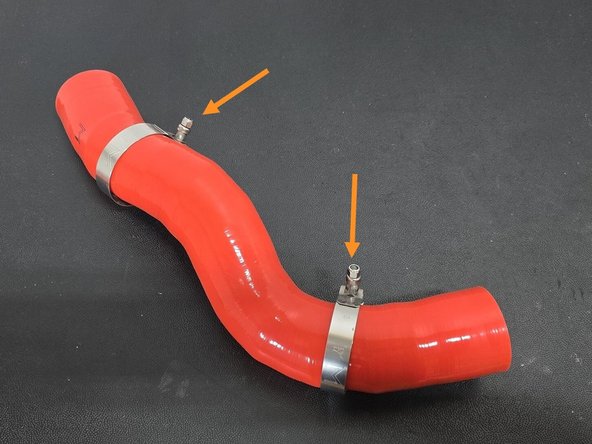

Locate the 27WON hot side boost tube

-

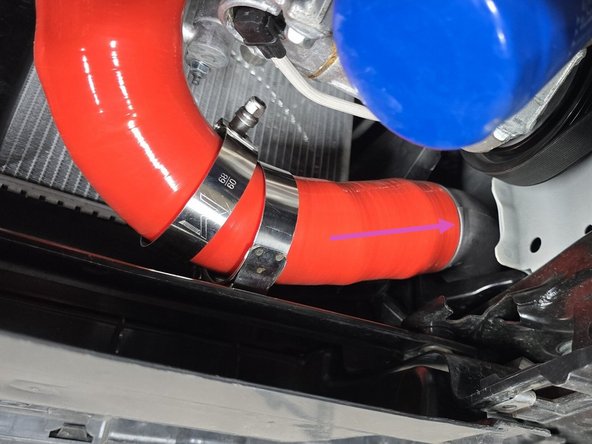

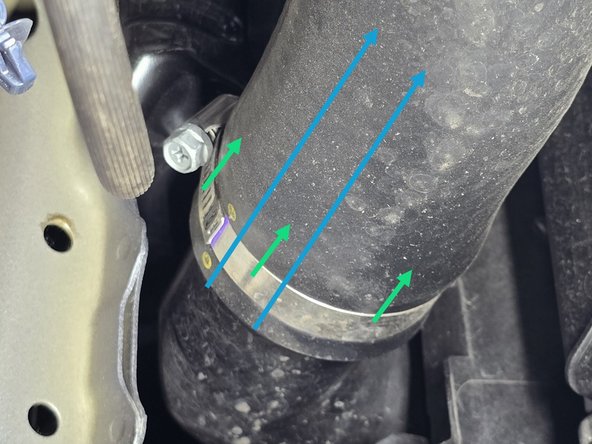

Install the two supplied 60-68mm clamps near the center of the boost tube as shown

-

The boost tube will go into the car in the orientation shown

-

Turbo side

-

FMIC side

-

Push the 27WON boost tube onto the turbocharger until flush with the stopper as shown

-

Push the 27WON boost tube onto the intercooler until flush with the stopper as shown

-

-

-

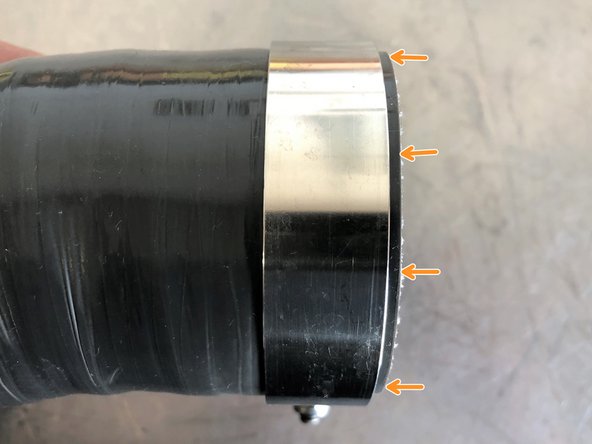

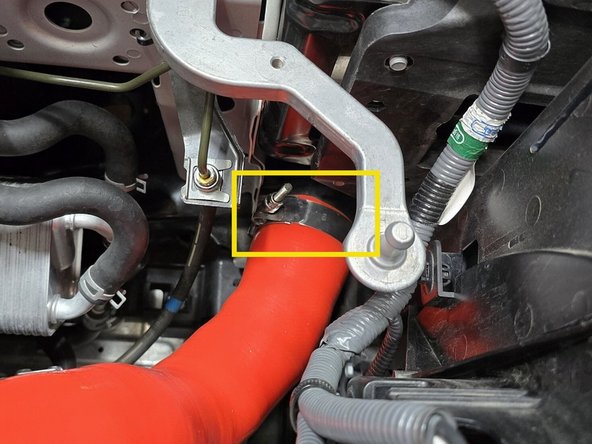

Image 1 on this page shows what we mean by "correctly positioning" the clamps. There should be a small gap between the clamp and the end of the silicone (2-4mm). This gap should be even all the way around the silicone. Use this image as a reference when tightening all supplied clamps

-

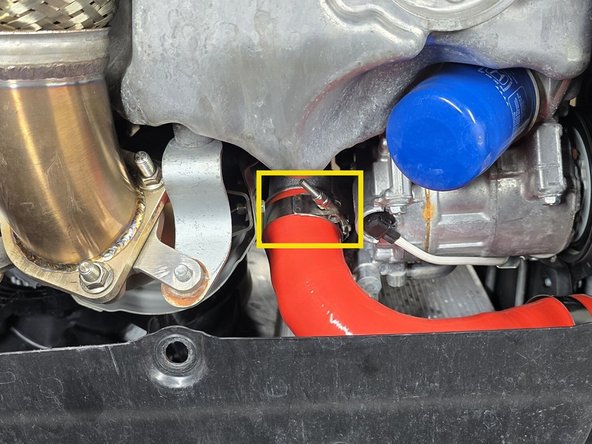

Correctly position the 60-68mm clamp on the turbocharger and tighten with a 10mm socket and 3/8" drive ratchet until the silicone starts to bulge slightly at the edge of the clamp

-

The clamp orientations shown are the easiest to access/tighten

-

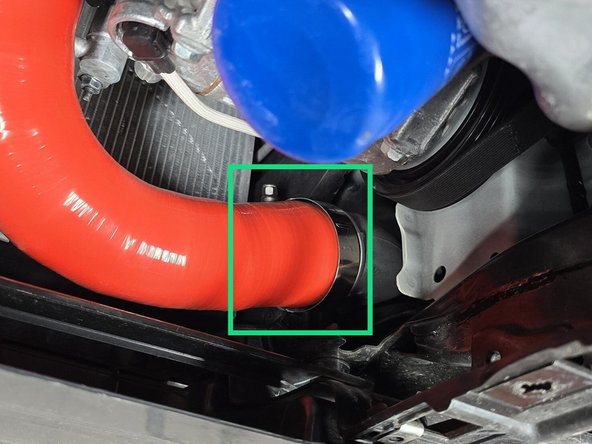

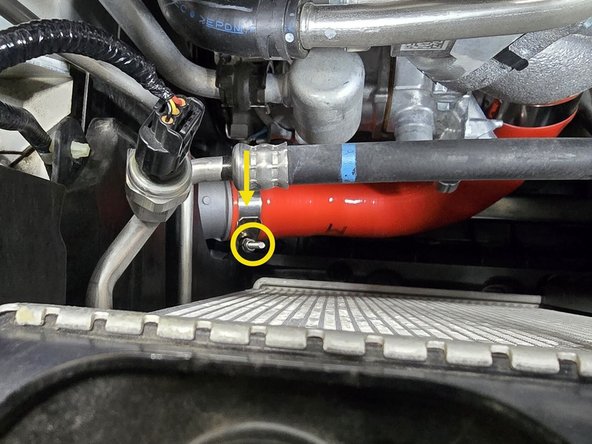

Correctly position the 60-68mm clamp on the intercooler as shown and leave to be tightened from above later

-

This clamp can be tightened now, but is much easier to reach from above with a 12" extension

-

-

-

Locate the lower portion of the OEM cold side boost tube. It's in the general area of the orange arrow

-

Loosen the clamp that connects the OEM cold side boost tube to the intercooler using a 10mm socket and 3/8" drive ratchet

-

Slide the clamp up the tube and out of the way

-

Pull the OEM boost tube free from the intercooler

-

-

-

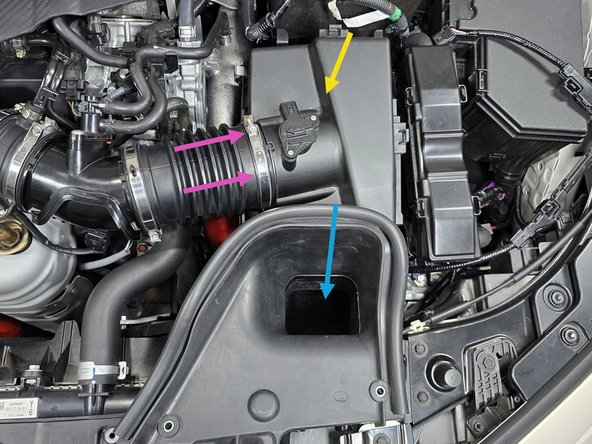

OE Intake removal is shown next. Skip to Step 14 and follow manufacturers instructions for aftermarket intakes

-

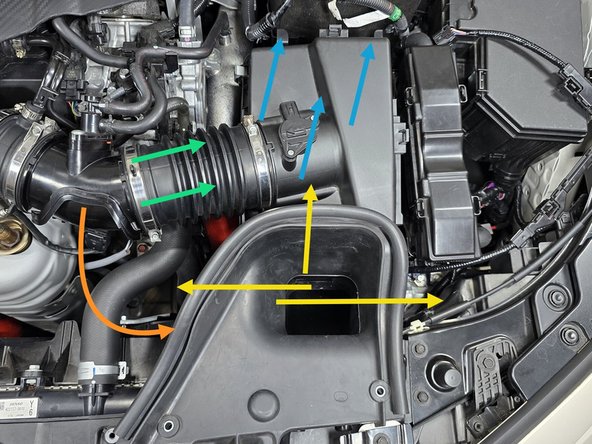

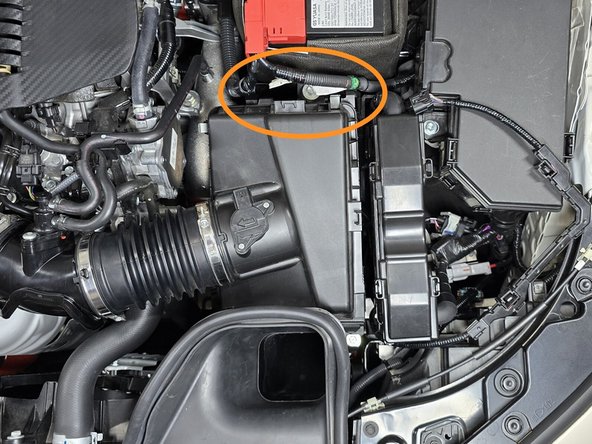

Moving back to the topside of the engine, begin removing the intake to gain access to the OEM cold side boost tube

-

Unplug the connector for MAF sensor by using your fingers to press down on the plastic clip and pulling the plug away from the airbox as shown

-

Using your finger press the two tabs shown towards the airbox, and lift on the wire loom to disconnect the loom from the airbox lid

-

Set the MAF sensor wire out of the way

-

-

-

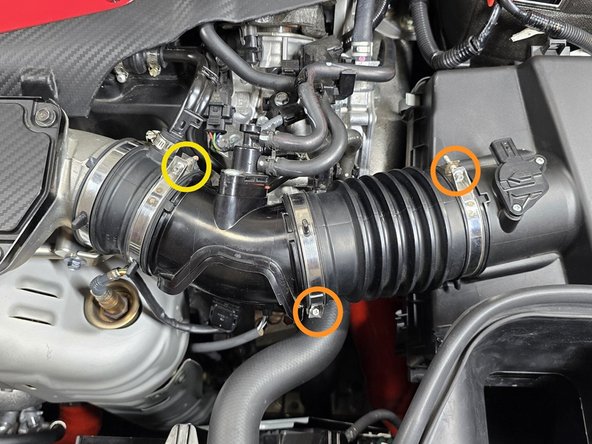

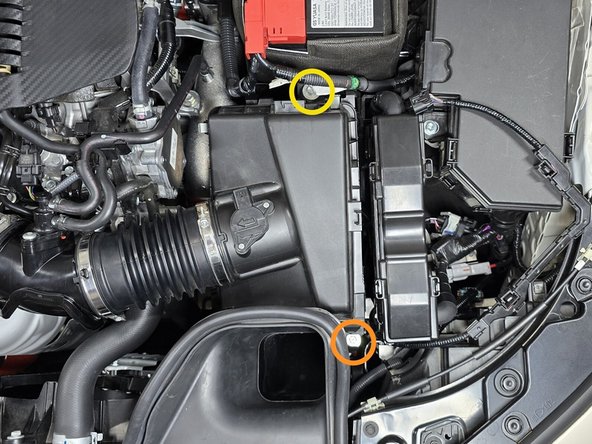

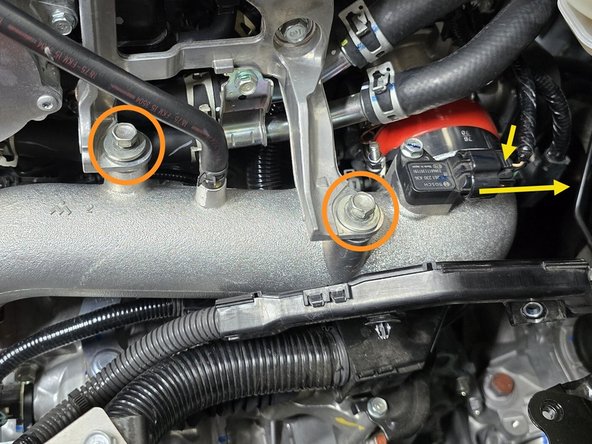

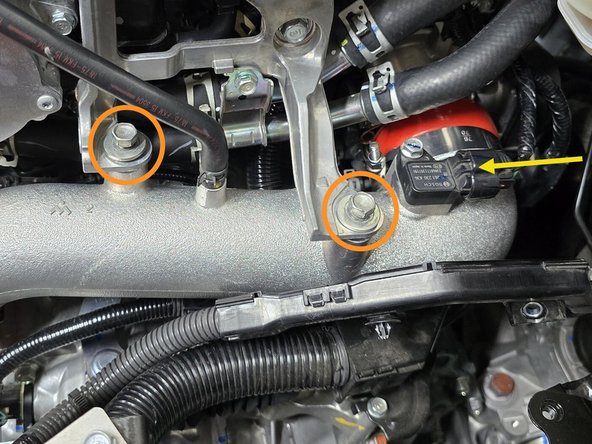

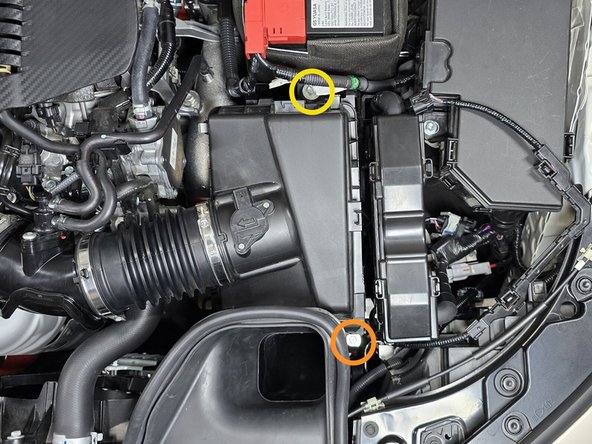

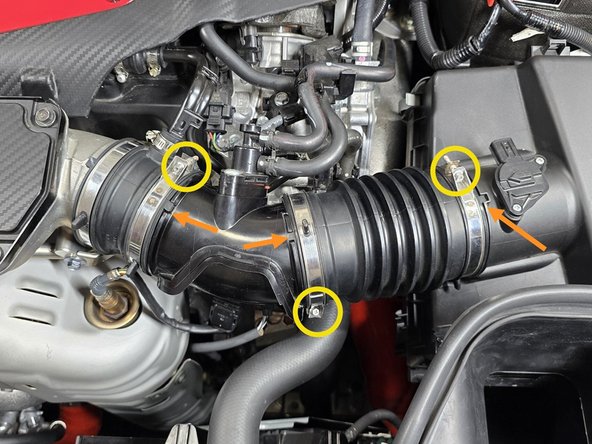

Use a 5.5mm socket and 3/8" ratchet or a small Phillips screwdriver to loosen the two intake clamps circled in orange

-

Use a 5.5mm socket and 3/8" ratchet or a small Phillips screwdriver to loosen the one EVAP elbow clamp circled in yellow

-

-

-

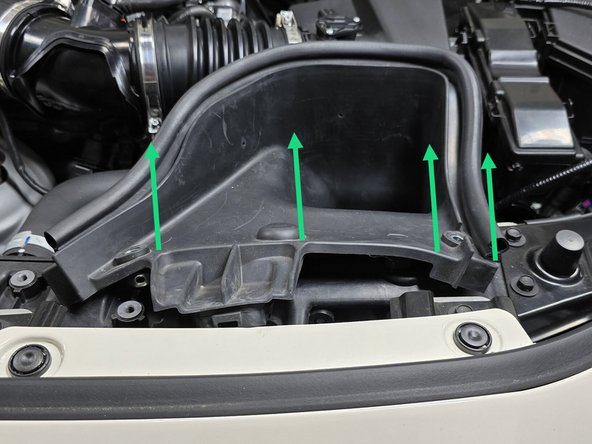

Use a 3/8" drive ratchet and a 10mm socket to remove two (2) bolts that hold the intake duct in place

-

Using your hand pull the rubber end of the duct out of its slot in the radiator shroud

-

This may take a bit of force the first time it comes out

-

-

-

Use a 3/8" ratchet, a long extension, and a 10mm socket to remove lower intake bolt

-

Use a 3/8" ratchet, a long extension, and a 10mm socket to remove the upper battery bracket bolt

-

-

-

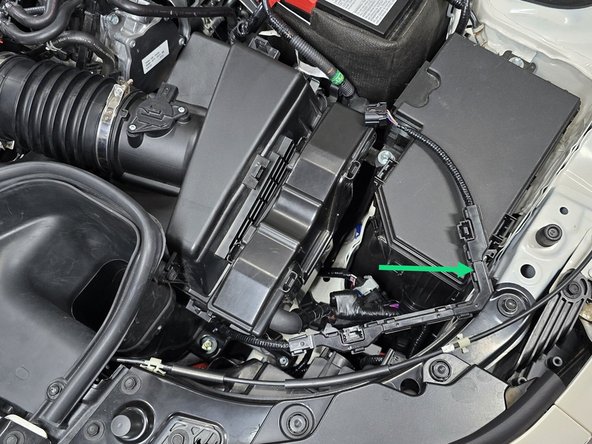

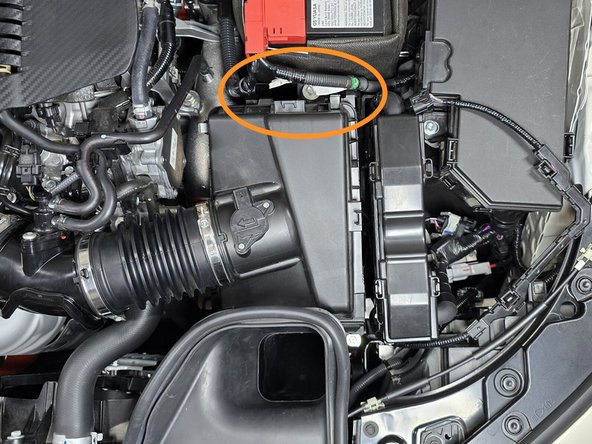

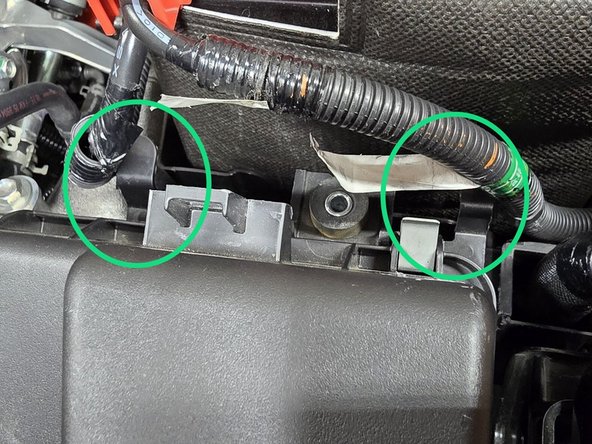

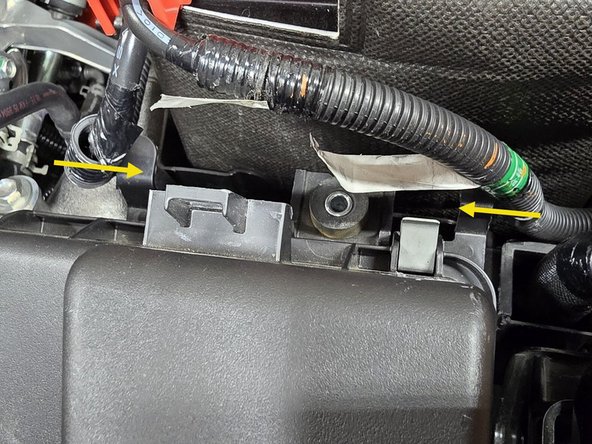

Locate the two positive battery cables that need to be freed from the upper airbox in order to remove the airbox

-

Using your fingers or a pair of needle nose pliers pinch the two battery cable clips and push them out of the airbox bracket

-

Only one side is shown, the other side is the same process

-

-

-

The airbox is still connected to the chassis with a rubber grommet and stud underneath the intake inlet in the area shown

-

Wiggle the inlet back and forth while lifting on the entire airbox to get it loose from the grommet as shown

-

Using your hand pull the accordion intake tube off of the hard plastic EVAP elbow as shown

-

With the intake tube now freed, pull the airbox assembly out of the engine bay

-

-

-

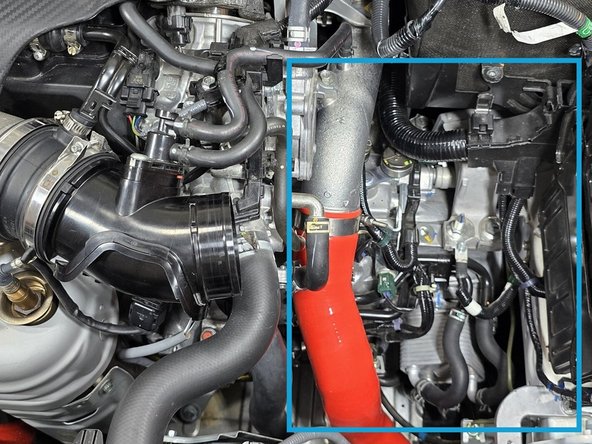

Locate the cold side boost tube

-

Using a 10mm socket and 3/8" drive ratchet, loosen the clamp where the OEM boost tube connects to the OEM cold pipe

-

Slide this clamp down the OEM boost tube

-

Pull the OEM boost tube free from the OEM cold pipe

-

Remove the OEM cold side boost tube from the engine bay

-

-

-

Locate the 27WON cold side boost tube

-

Install the two supplied 63-71mm clamps away from the ends of the silicone as shown

-

Position the boost tube in the orientation shown

-

Cold pipe end

-

Intercooler end

-

Push the 27WON boost tube onto the intercooler until flush with the stopper as shown

-

Push the 27WON boost tube onto the cold pipe until flush with the stopper as shown

-

-

-

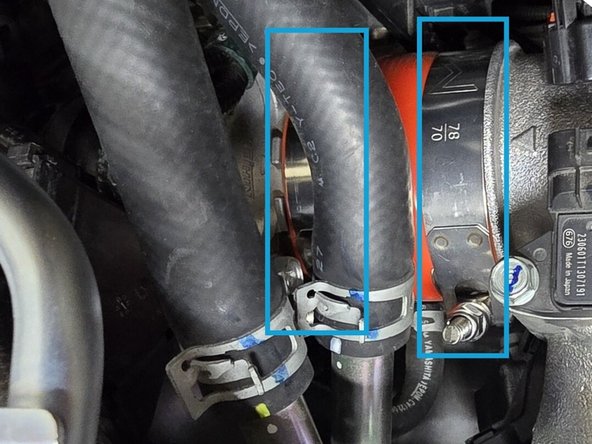

Correctly position the 63-71mm clamp over the cold pipe and tighten with a 10mm socket and 3/8" drive ratchet until the silicone starts to bulge slightly at the edge of the clamp

-

Correctly position the 63-71mm clamp over the Intercooler and tighten with a 10mm socket, a 12" extension, and a 3/8" drive ratchet until the silicone starts to bulge slightly at the edge of the clamp

-

See Step 6 for correct clamp positioning

-

The clamp orientations shown are easy to access and provide clearance to airboxes and intakes

-

-

-

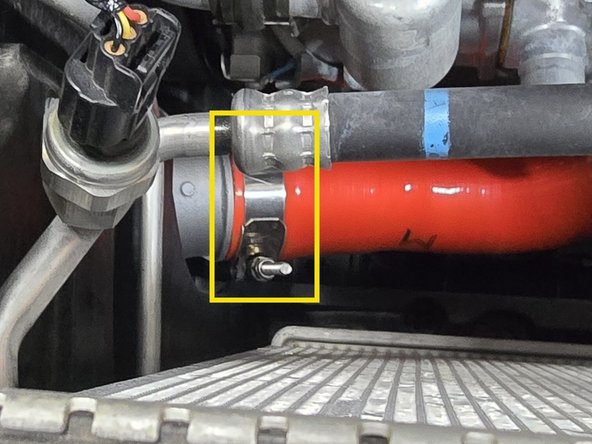

If you tightened this clamp while under the car, you can skip this step

-

Looking down between the radiator and turbocharger you can get a straight shot at the connection between the hot side boost tube and intercooler

-

Correctly position the 60-68mm clamp on the intercooler and tighten with a 10mm socket, a 12" extension, and 3/8" drive ratchet until the silicone starts to bulge slightly at the edge of the clamp

-

If the 12" extension does not provide enough clearance, a longer extension or a stack of multiple extensions can provide better reach

-

-

-

The battery, and battery tray will need to be removed for easy access to the throttle body silicone

-

If you have an FSTB installed it will need to be removed before proceeding

-

Loosen the nut on the negative battery cable with a 10mm socket and a 3/8" drive ratchet then remove the negative cable from the battery. Tuck the cable out of the way

-

Loosen the nut on the positive battery cable with a 10mm socket and a 3/8" drive ratchet then remove the positive cable from the battery. Tuck the cable out of the way

-

Loosen one of the nuts on the battery tiedown with a 10mm socket and a 3/8" drive ratchet then remove the hook and battery tiedown from the battery

-

With the cables and tiedown out of the way lift the battery out of the engine bay and set it to the side

-

Note that there may be a handle on your battery that makes removal easier

-

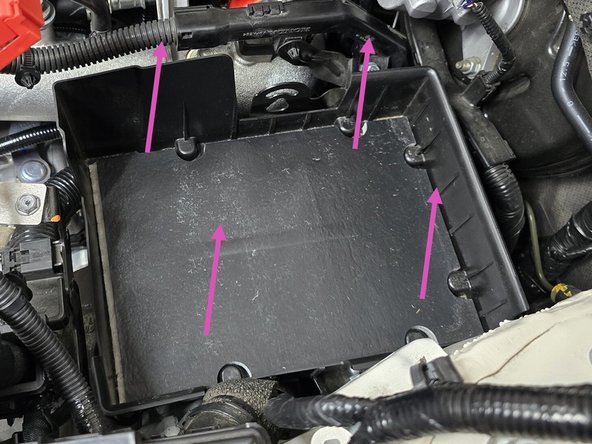

Remove the plastic battery tray from the engine bay to expose the lower metal battery tray

-

-

-

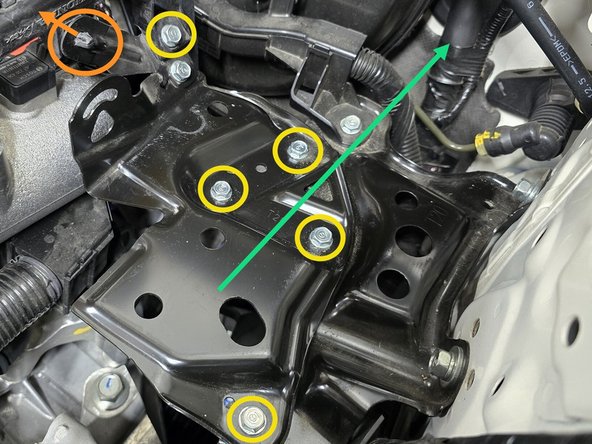

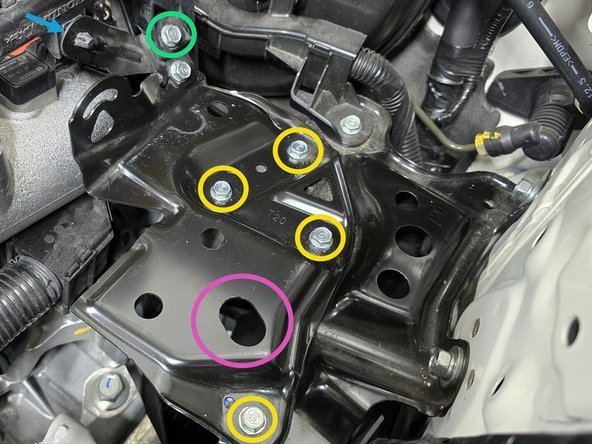

Use your fingers or a pair of pliers to pinch the clip circled in orange and push it out of the bracket

-

Use a 10mm socket, a 6" extension, and a 3/8" drive ratchet to remove the five bolts circled in yellow

-

With the lower battery tray free, remove it from the engine bay as shown

-

-

-

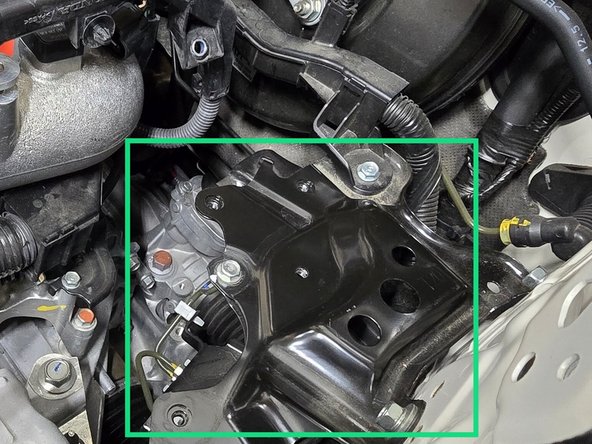

The cold pipe will need to be unbolted from the engine block brackets to allow the necessary movement to remove the throttle body silicone

-

Use a 12mm socket, a 6" extension, and a 3/8" drive ratchet to remove the two mounting bolts circled in orange

-

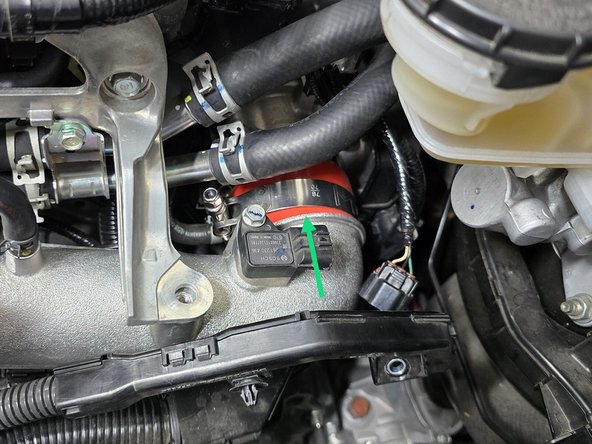

Unplug the MAP sensor by pressing down on the mounting tab, and pulling the plug towards the firewall

-

-

-

Use a 10mm socket, a 6" extension, and a 3/8" drive ratchet loosen the two hose clamps securing the OEM silicone

-

With both clamps loose, pull the cold pipe towards the drivers side of the vehicle and out of the throttle body silicone

-

With the cold pipe out of the way, remove the OEM silicone as shown

-

-

-

Loosely place the 70-78mm clamps on the 27WON silicone

-

This silicone is not directional, so the orientation of the silicone itself is not important

-

While holding the cold pipe out of the way, push the silicone over the throttle body until flush with the stopper on the throttle body

-

Push the cold pipe into the silicone until flush with the stopper on the cold pipe as shown

-

Correctly position the 70-78mm clamps on the throttle body and cold pipe, and tighten with a 10mm socket, a 6" extension, and 3/8" drive ratchet until the silicone starts to bulge slightly at the edge of the clamp

-

-

-

Thread the two mounting bolts into the cold pipe as shown then use a 12mm socket, a 6" extension, and a 3/8" drive ratchet to tighten them down

-

Plug the MAP sensor back in as shown

-

-

-

The lower battery bracket will need to align with the four holes circled in orange when reinstalled

-

Thread the four mounting bolts as shown, then use a 10mm socket, a 6" extension, and a 3/8" drive ratchet to tighten them down

-

Thread the wire mounting bolt through the plastic loom as shown, then use a 10mm socket, a 6" extension, and a 3/8" drive ratchet to tighten the bolt down

-

Press the wire mounting clip through the bracket as shown until it "clicks" into place

-

The plastic battery tray will slot into the hole circled in pink

-

-

-

Place the plastic battery tray into the engine bay in the orientation shown, the plastic alignment pin on the bottom will slot into the hole circled in the last step

-

Place the battery into the plastic tray in the orientation shown

-

Place the battery tie down over the battery in the orientation shown, with the shorter hook towards the drivers side of the vehicle

-

Place the tie down hooks into their respective holes, then tighten down the two nuts with a 10mm socket, and a 3/8" drive ratchet until snug

-

If these are too tight the tie down can damage the battery cap

-

Place the positive cable over the positive terminal, then use a 10mm socket, and a 3/8" drive ratchet to tighten the terminal clamp

-

Place the negative cable over the negative terminal, then use a 10mm socket, and a 3/8" drive ratchet to tighten the terminal clamp

-

-

-

OE Intake installation is shown next. Skip to Step 31 and follow manufacturers instructions for aftermarket intakes

-

When reinstalling the airbox there is a rubber grommet on the bottom of the box that must fit on an aluminum peg in the engine bay

-

Insert the airbox into the engine bay in a similar manner that it was removed

-

The front will sit in an approximately correct location while the back pivots downward

-

Use care when maneuvering the rear brackets around the battery cables so as to not damage the cables

-

Press the front of the airbox down over the aluminum peg mentioned above

-

You should be able to feel the peg insert into the rubber grommet

-

Press the OEM intake tub over the airbox lid as shown

-

-

-

The battery cables will need to be reconnected to the airbox in the location shown

-

Press the plastic clips on the battery cables into the mounting holes on the airbox as shown

-

-

-

The airbox may need to be shifted around to align the mounting bolts with their matching threaded holes

-

Using a 10mm socket, and a 12" extension hand thread the lower mounting bolt

-

Use the same combination of tools and a 3/8" drive ratchet to tighten down the lower airbox mounting bolt

-

Using a 10mm socket, and a 12" extension hand thread the upper battery bracket bolt

-

Use the same combination of tools and a 3/8" drive ratchet to tighten down the upper battery bracket bolt

-

-

-

Use your hand to press the intake inlet back into its slots on the radiator shroud

-

This will require a bit of force, and some moving back and forth to ensure it is fully seated the first time

-

Hand thread the two inlet mounting bolts in the locations shown

-

Use a 10mm socket and a 3/8" drive ratchet to tighten both bolts

-

-

-

Verify the OE intake tube and EVAP elbow are fully seated in the locations shown

-

Use a 5.5mm socket and 3/8" ratchet or a small Phillips screwdriver to tighten the three intake clamps circled in yellow

-

Press the MAF wire loom into the mounting tabs on the airbox lid as shown

-

Plug the MAF sensor back in

-

-

-

The final bit of this install will be done under the vehicle

-

Lift the metal section of the undertray into position

-

The front edge of the metal will fit over the top of the rear edge of the plastic section of the undertray

-

To secure, push the skidtray forwards onto the two tabs that will hold it in position

-

Reinstall the four Phillips head screws and tighten until tight using a Phillips screwdriver

-

Reinstall the four quarter-turn screws and tighten using a large Flathead screwdriver. This will "click" into position when tight

-

Reinstall the two Philips head screw and tighten using a Philips screwdriver

-

-

-

This completes the installation of your 27WON Performance Boost Tubes

-

We hope you were impressed with your 27WON experience and love your new Boost Tubes for years to come. Email us at sales@27won.com or call us at 571-271-0271 with any questions or concerns

-

Please Leave a review here: https://store.27won.com/honda-civic-type...

-

Stay Connected with the latest developments with the 27WON Monthly Newsletter: https://store.27won.com/27won-newsletter...

-

See the latest Products and Tech Videos from 27WON with a quick Subscribe: https://www.youtube.com/channel/UCF7uI0N...

-

Share your experience using #27WON on Instagram and Facebook

-