Introduction

In this installation guide we have provided step by step instructions to remove the OEM downpipe and install the 27WON Performance Downpipe for Civic Type R

Advisory:

- The engine bay will be hot after recent vehicle operation. Allow the vehicle to cool or use a fan to cool the engine bay before working on the vehicle.

- Working under the vehicle requires a safe and sturdy location for the vehicle to sit on jackstands.

Tools

- 3/8" Ratchet

- 3/8" 3 in Extension

- 1/4" Ratchet

- 1/4" Ratchet Extension

- 3/8" Torque Wrench

- 12mm Wrench

- 14mm Wrench

- Wrench 22mm

- 5.5mm Socket

- 10mm Socket

- 10mm Socket - Deep

- 12mm Socket

- 14mm Socket

- 22mm Oxygen Sensor Socket

- 5mm Allen Key Socket

- 3/8" Drill Bit

- Needle Nose Pliers

- Pliers - Small

- Flathead Screwdriver

- Hydraulic Jack

- Jack Stand × 2

- WD-40 or other penetrating fluid

- Silicone Lubricant Spray

- Shop Towels/Rags

-

-

First and foremost; THANK YOU for becoming a part of the 27WON Family. We hope to REDEFINE your experience of the aftermarket with the highest level Parts, Customer Service, Packaging, & Support

-

These instructions were written with a 2018 Honda Civic Type R

-

Catted Downpipes are intended for racing use only. Installation and use are at the customers own risk

-

-

-

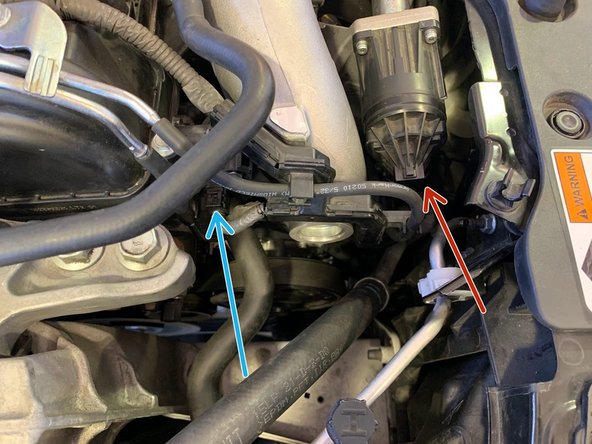

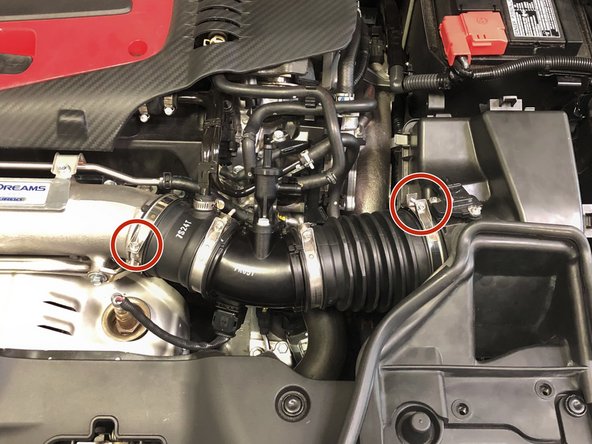

Unplug the MAF sensor by pushing down on the tab (red circle) on top of the wiring connector

-

-

-

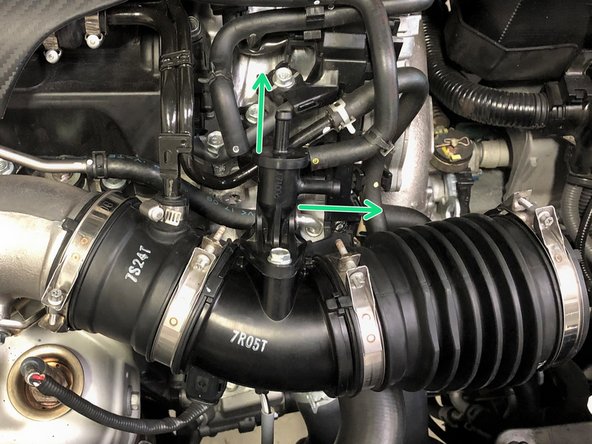

Use needle nose pliers to loosen both OEM spring clamps and slide them up the hoses

-

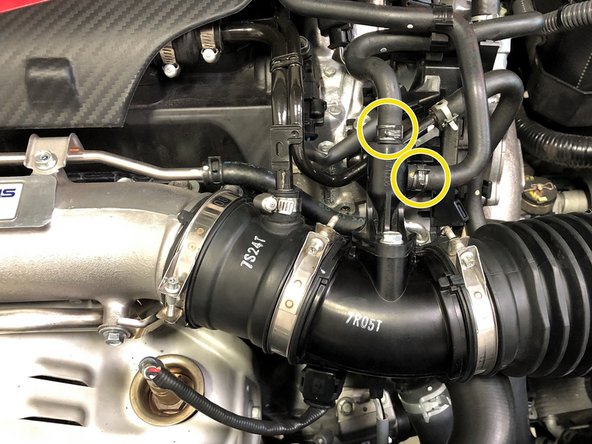

Pull the Boost Feed and EVAP Dump hoses off the EVAP solenoid

-

-

-

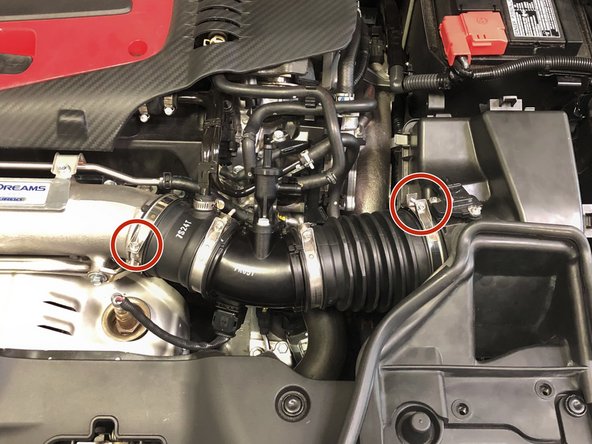

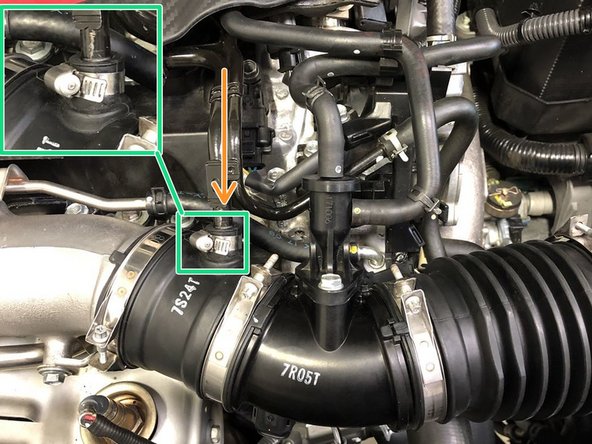

Using the 5.5mm socket and ratchet, loosen the two OEM clamps securing the intake tube

-

Remove the valve cover breather pipe from the intake tube

-

This breather pipe is secured with a permanent OEM clamp. This clamp cannot be removed easily so the pipe will need to be pulled free without removing the clamp. This can be difficult the first time. This permanent clamp will be replaced with the provided regular hose clamp during re-installation

-

Remove the OEM intake tube from the vehicle

-

-

-

Undo upper oxygen sensor electrical pigtail and let loose out of the way

-

-

-

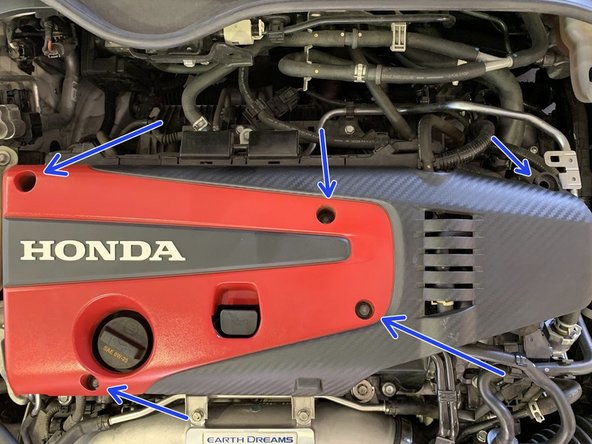

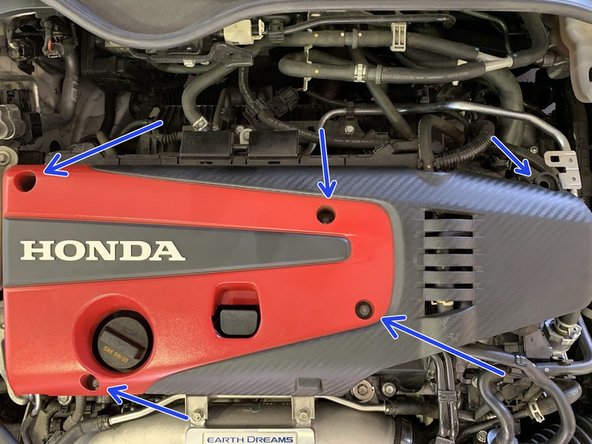

Use a10mm socket to remove the 5 bolts holding the engine cover

-

Remove the engine cover

-

-

-

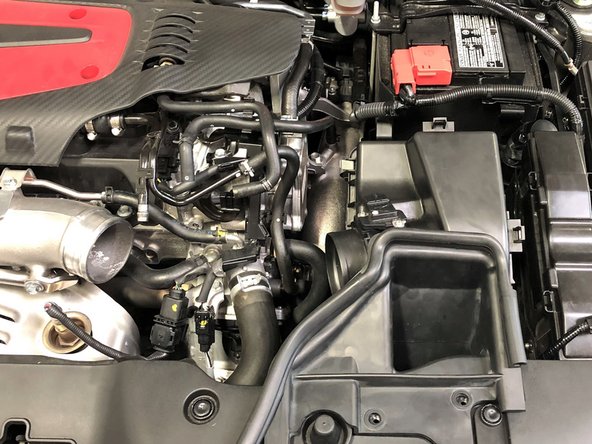

Remove (2) 10mm bolts securing the hard water line to the inlet pipe and move out of the way

-

Remove (2) 10mm bolts securing lower hard water pipe

-

-

-

Undo 10 mm bolt on the inlet pipe as shown

-

-

-

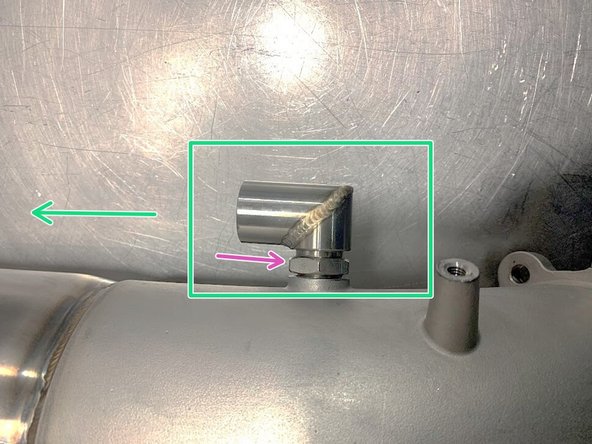

There are 2 bolts holding this bracket. The lower one is well hidden (purple arrow)

-

Using ¼ inch ratchet, 10mm deep socket, and 3 inch extension, remove the 10mm bolt shown

-

Remove the lower 10mm bolt as shown

-

-

-

Unplug electrical pigtail of electronic wastegate

-

-

-

Unclip the vacuum hose from the clips on the vacuum line retainer bracket

-

-

-

Using needle nose pliers, undo the clamp as shown and free the silicone hose from the hardline

-

Follow the line down and find the lower clamp holding the hose

-

Undo the lower clamp and free the silicone hose from the receiver

-

Remove the silicone hose from the car and set aside

-

-

-

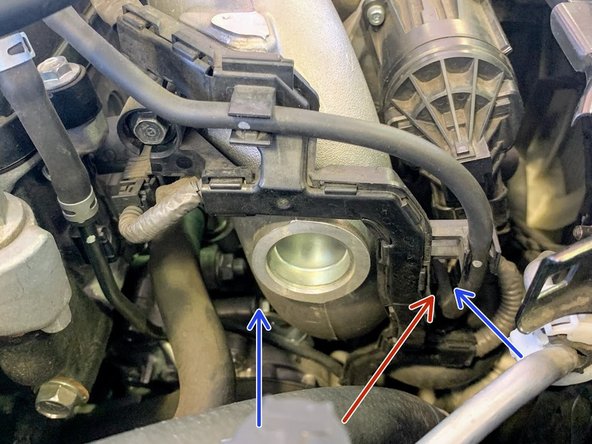

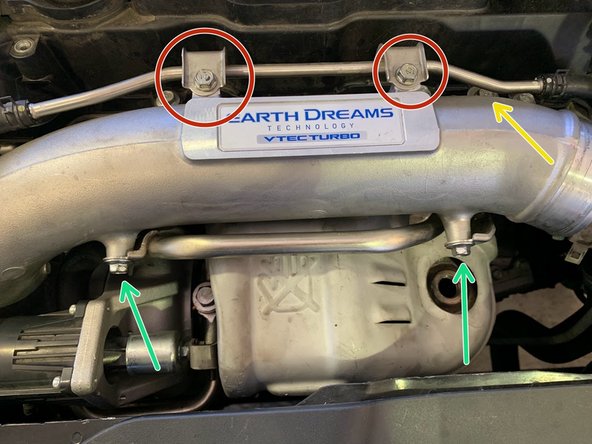

Turbo inlet pipe assembly is shown off the car here because the bolts are hard to see installed on vehicle

-

The (2) 10mm bolts are shown off the car to better demonstrate their location

-

Remove the Inlet Pipe by removing the (2) 10mm bolts shown above, a deep 10mm socket and ~3" extension work best here

-

-

-

Using a 22mm socket remove the upper oxygen sensor

-

Set the sensor out of the way

-

-

-

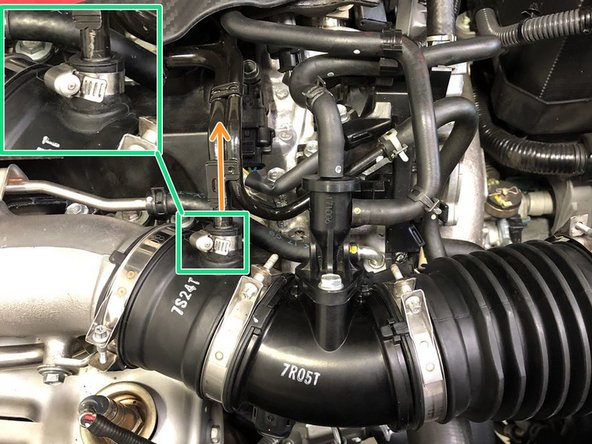

Using a 12mm socket and ratchet, remove the (2) 12mm bolts from the upper part of the heat shield

-

It is very difficult to remove the lower bolt from the heat shield from the engine bay (shown off the car, orange arrow). We advise to remove this bolt from underneath the car

-

Using a 12mm wrench, remove the lower 12mm bolt from the heat shield

-

-

-

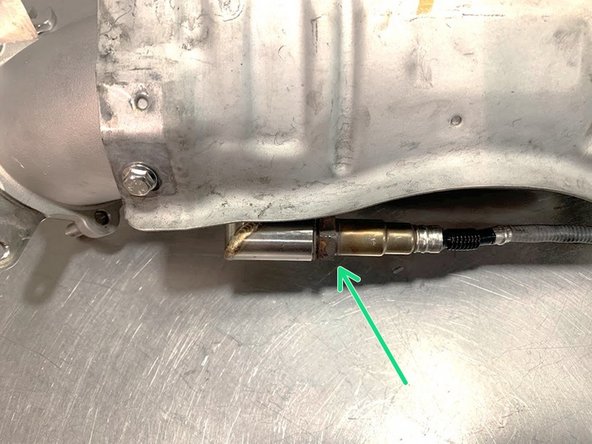

Unplug the lower oxygen sensor electrical pigtail connector located next to the upper oxygen sensor connector

-

-

-

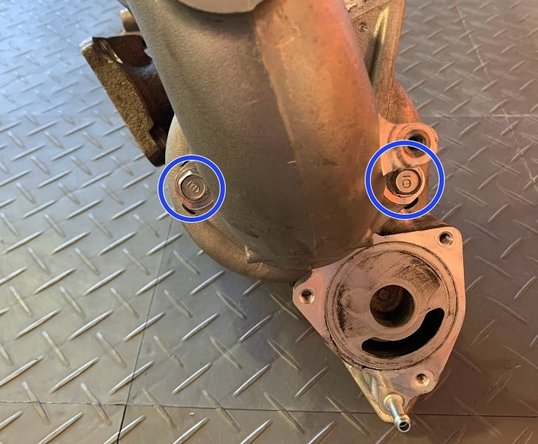

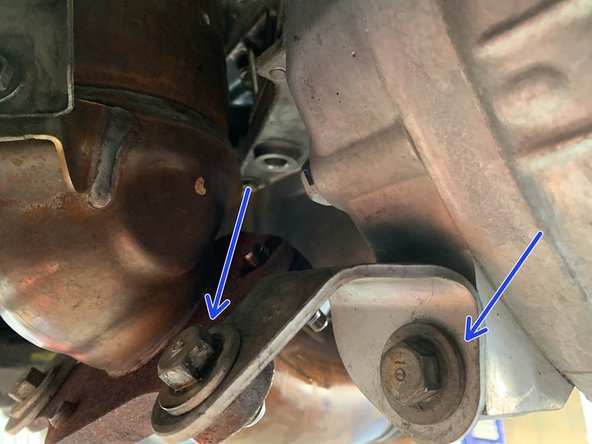

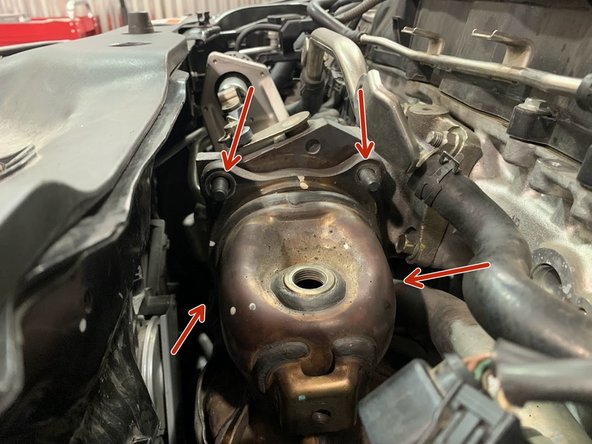

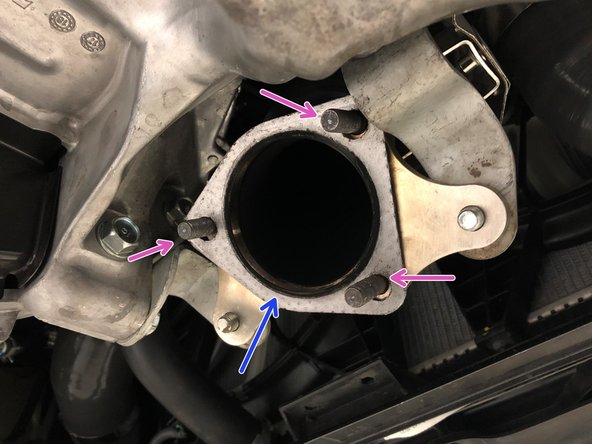

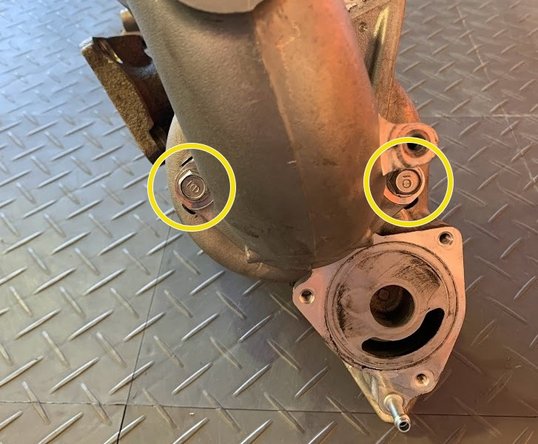

There are 2 nuts and 2 bolts that mount the Downpipe to the Turbo. Soak them with Penetrating fluid prior to attempting removal

-

Break loose the (2) 14mm bolts (blue arrows) and the (2) 14mm nuts (red arrows)

-

Using a 14mm socket, remove the 2 nuts (red arrows)

-

Using a 14mm socket remove the 2 bolts (blue arrows) as shown

-

-

-

Jack up your car and secure it with jack stands as you will need to get underneath

-

-

-

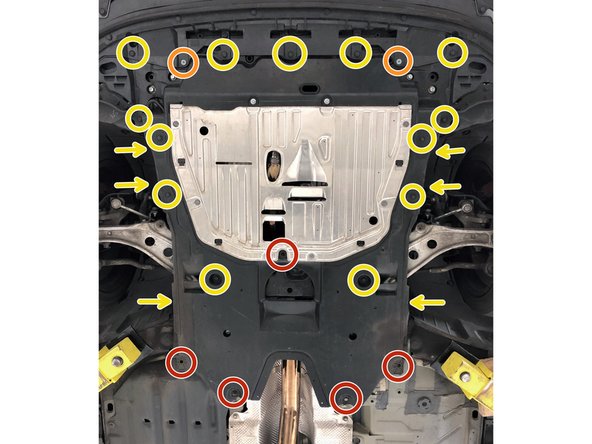

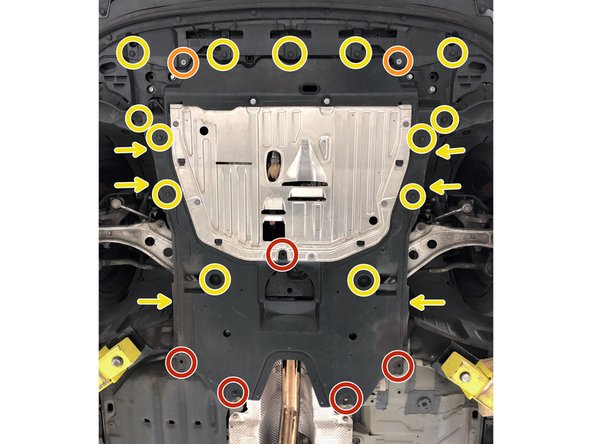

Locate the engine undertray to gain access to the exhaust front-pipe

-

Take pictures or take a good look at how the under tray fits with the other under body shields to help with easier reinstallation

-

Use a 10mm socket & ratchet to remove the five 10mm bolts (red circles)

-

Use a 5mm Allen Key/Allen Socket to remove the two (2) Allen head bolts (orange circles)

-

Use a Flathead screwdriver or push clip removal tool to remove the 19 push clips from the under tray (yellow circles and arrows)

-

For clarity on the push clips on the sides of the under tray (labeled with the arrows) please proceed to the next step

-

-

-

The images in this step show the push clips on the side of the under tray. These are labeled with the arrows in the previous step

-

Passenger side shown, please repeat for the driver side before removing the under tray

-

Remove the engine under tray from the vehicle

-

-

-

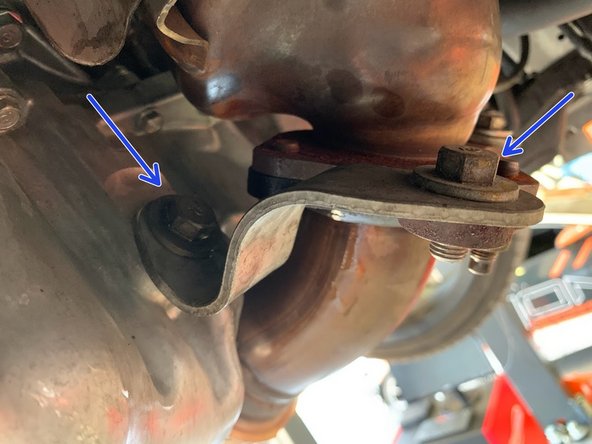

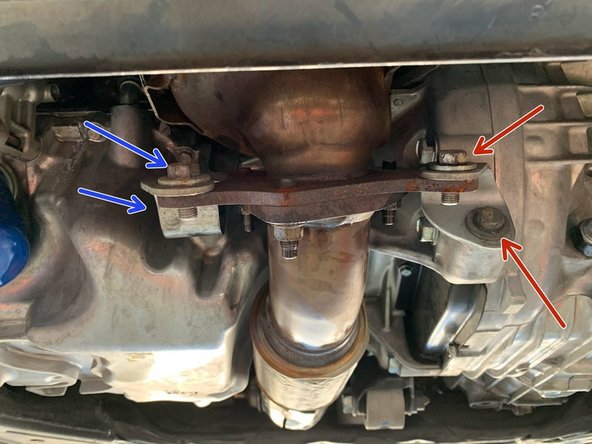

Using a 14mm socket and a 14mm wrench , undo the (4) bolts for the downpipe brackets as shown

-

Remove both of the brackets and set them aside

-

-

-

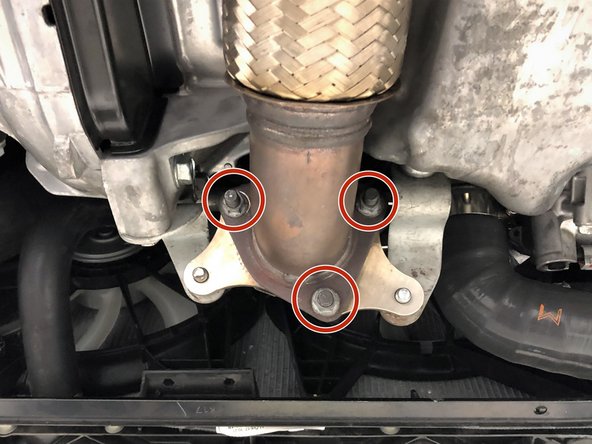

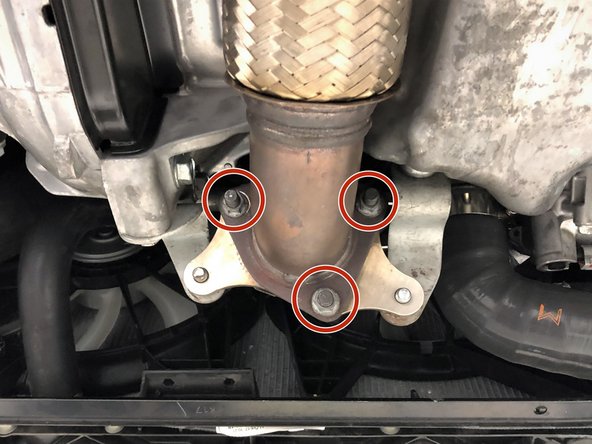

Use a 14mm socket and ratchet to remove the three nuts that connect the front-pipe to the downpipe

-

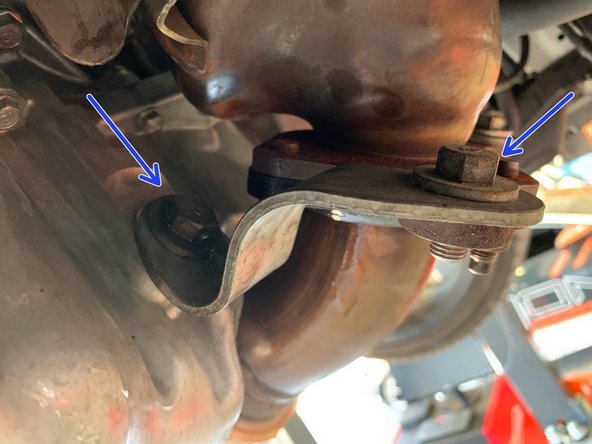

Pull the rubber hanger on the OE front-pipe free from the hanger rod on the chassis in the direction shown

-

Usually the studs will remain in the downpipe causing issues when removing the downpipe. Pry the downpipe from front pipe by sticking a screwdriver in between the downpipe and the forward pipe

-

Remove the Downpipe from underneath the car

-

-

-

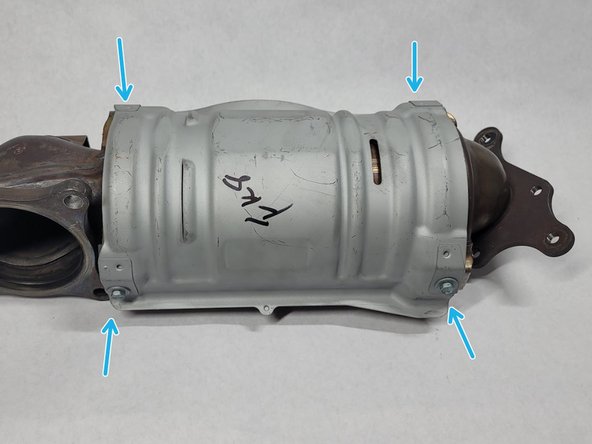

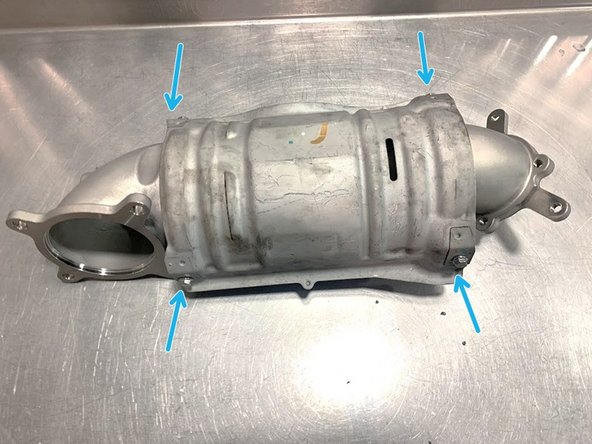

Remove four (4) bolts from the lower heat shield using a 10mm socket or wrench. Set aside bolts. They will not be reused

-

Use of exhaust spacer in this way on public roads and highways is prohibited. This is for racing use only

-

O2 Wire Extension is needed for install without exhaust spacer. This is not included with the downpipe

-

Install provided exhaust spacer on 27WON Downpipe

-

Twist lock nut fully up spacer threads

-

Install spacer almost to lock nut. Make sure it's pointing as shown with the green arrow towards the catalyst

-

Use 22mm wrench to lock nut against the downpipe

-

-

-

Swap lower oxygen (O2) sensor from OE downpipe to 27WON Downpipe

-

-

-

Drill out the four holes in OE heat shield using 3/8" Drill Bit

-

The heat shield is sharp and can catch on the bit. Use a vice to hold the heat shield

-

Install lower heat shield on 27WON Downpipe using four (4) provided M6x1.0x10mm flanged bolts

-

-

-

Clean and place OE gasket as shown

-

Shown without OE studs installed. Leave them in place

-

Reinstall the downpipe onto the turbo over OE studs

-

OE Downpipe Shown

-

Thread (4) OE nuts onto the studs with anti-seize. Torque to 40 ft-lb

-

-

-

Reconnect the lower oxygen sensor electrical pigtail as shown

-

-

-

Outlet flange has five threaded holes. Three are M10x1.50 and two are M10x1.25. Use caution not to cross-thread

-

Install the three provided M10x1.50 studs into the downpipe outlet flange as shown

-

Do not use M10x1.25 hardware here. Use caution not to cross thread these three holes

-

Place provided 2+1 MLS exhaust gasket between downpipe and front pipe

-

Please note, a prototype gasket is shown, your gasket will differ slightly in appearance

-

Align the downpipe with the front pipe and reinstall the (3) OE 14mm nuts. Torque to 30-40 ft-lb

-

Reinstall the exhaust hanger for the front pipe

-

-

-

OE Downpipe Shown

-

Align the left side bracket and reinstall the (2) OE 14mm bolts with anti-seize. Torque to 30-40 ft-lbs

-

Align the right side bracket and reinstall the (2) OE 14mm bolts with anti-seize. Torque to 30-40 ft-lbs

-

-

-

Lift the under tray into position

-

Reinstall the five 10mm bolts with a 10mm socket & torque wrench. Torque to 6-8 lb-ft

-

Reinstall the two 5mm socket flange bolts with the 5mm Allen key & torque wrench. Torque to 6-8 lb-ft

-

Reinstall the 19 push clips at the bottom of the undertray and the sides

-

For clarity on the push clips on the sides of the under tray (labeled with the arrows) please see the next step

-

-

-

The images in this step show the push clips on the side of the under tray. These are labeled with the arrows in the previous step

-

-

-

Install the (2) 12mm bolts from the upper part of the heat shield

-

It is very difficult to install the lowest bolt from the heat shield from above (as shown off the car). We advise to install this bolt from underneath

-

Install the lower 12mm bolt from the heat shield

-

-

-

To demonstrate the location of the mounting screws, the turbo inlet pipe is shown off the car

-

Use the OE (2) 10mm bolts to secure turbo inlet pipe to turbo. Torque to 16-18 ft-lb

-

-

-

Reinstall the (2) OE 10mm bolts to mount the top hard line to the intake pipe

-

Reinstall the (2) OE 10mm bolts to mount the bottom hard line to the intake pipe

-

Reinstall the OE 10mm bolt to mount the intake pipe as shown

-

-

-

There are 2 bolts holding this bracket. The lower one is well hidden (purple arrow)

-

Using the OE 10mm bolt reinstall the upper part of the vacuum line bracket as shown

-

Using the OE 10mm bolt reinstall the lower part of the vacuum line bracket as shown

-

-

-

Plug elect pigtail of electronic wastegate

-

Follow the wire up and reconnect the other end of the electrical harness as shown

-

-

-

Reinstall the upper oxygen sensor using the 22mm oxygen socket. Torque to 30 ft-lbs

-

Reconnect wiring harness for upper oxygen sensor

-

-

-

Reinstall the intake tube as shown and secure the clamps with a 5.5mm socket

-

Replace the clamp with the provided 14-27mm hose clamp

-

Use needle nose pliers to clamp the OEM spring clamps for the EVAP silicon Boost feed and EVAP dump hoses

-

-

-

Use a 10mm socket and install the 5 bolts to hold the engine cover

-

-

-

Some smell and faint smoke can be present on first start-up. This is normal and will not happen after the 2nd or 3rd heat cycle.

-

To get the best performance from your Performance Downpipe, we highly recommend a custom tune. OTS maps will work for some people

-

A custom tune for your specific vehicle with your specific modifications will provide the best performance for your Civic and the location you live in

-

-

-

This completes the installation of your 27WON Performance FK8 Downpipe

-

We hope you were impressed with your 27WON experience and love your new downpipe for years to come. Email us at sales@27won.com or call us at 571-271-0271 with any questions or concerns

-

Please Leave a review here: https://store.27won.com/2017-2021-civic-...

-

Stay Connected with the latest developments with the 27WON Monthly Newsletter: https://store.27won.com/27won-newsletter...

-

See the latest Products and Tech Videos from 27WON with a quick Subscribe: https://www.youtube.com/channel/UCF7uI0N...

-

Share your experience using #27WON on Instagram and Facebook

-