Introduction

In this installation guide we have provided step by step instructions to remove the OEM turbo Bypass Valve and install the 27WON Bypass Valve on a 2022 Civic Si equipped with Gin Turbo. Other 2022+ Civic and Integra 1.5T models will be similar. OE turbo install will be similar.

- Working under the vehicle requires a safe and sturdy location for the vehicle to sit on jackstands.

- The exhaust piping, turbocharger, and cooling system will be hot after recent vehicle operation. Allow the vehicle to cool or use a fan to cool the exhaust components before working on the vehicle.

Tools

-

-

First and foremost; THANK YOU for becoming a part of the 27WON Family. We hope to REDEFINE your experience of the aftermarket with the highest level Parts, Customer Service, Packaging, & Support

-

You will proceed to remove the OEM Bypass Valve from the vehicle in the coming steps

-

Removal of the Turbo Inlet Pipe is recommended to access one of the fasteners attaching the OEM BPV (Bypass Valve) to the Turbo. Due to the style of fastener used (Torx bit), they are easy to strip. This style of fastener is not reused. New hardware is supplied for reinstallation of the 27WON BPV making any future removal or maintenance easier

-

-

-

Use a 5.5mm socket and 1/4" ratchet to remove the two (2) clamps (red markups) securing the accordion style intake air tube

-

Remove intake air tube from car and set aside

-

-

-

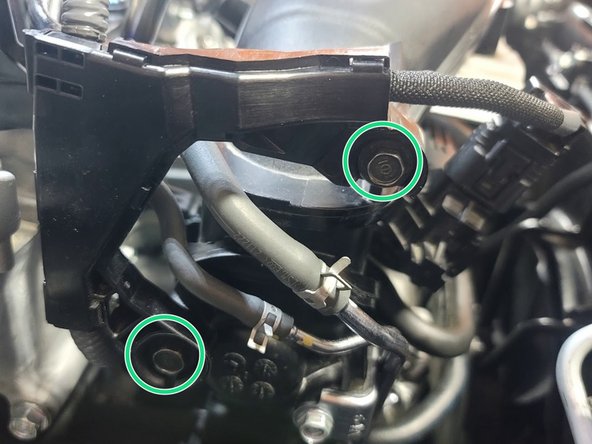

Remove two (2) screws from Turbo Inlet Pipe (TIP) EVAP valve with T30 Torx Bit

-

Pop both EVAP lines from clip

-

Tuck EVAP valve out of the way as shown (blue box)

-

-

-

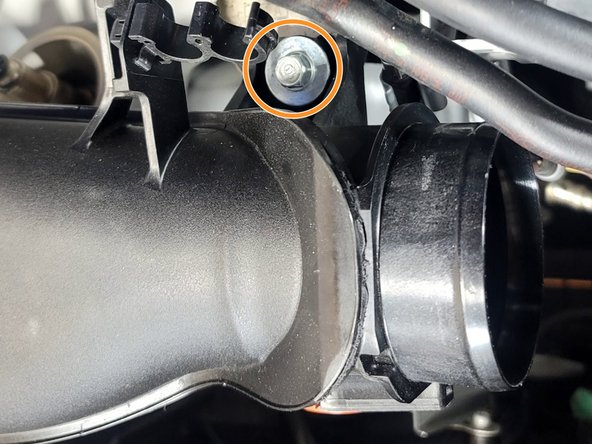

Use 10mm socket and ratchet to remove bolt from TIP bracket near inlet

-

-

-

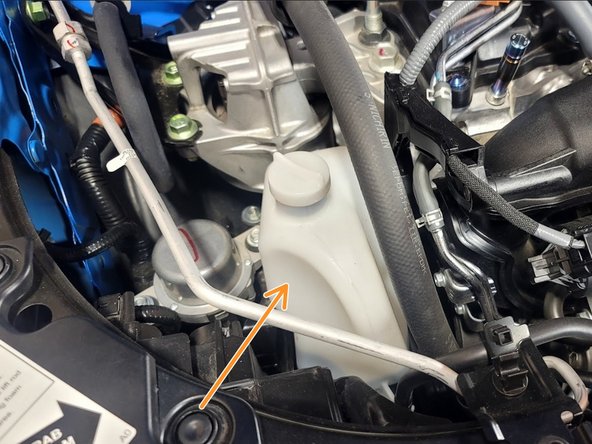

Pull up on reservoir to free from bracket and relocate as shown

-

-

-

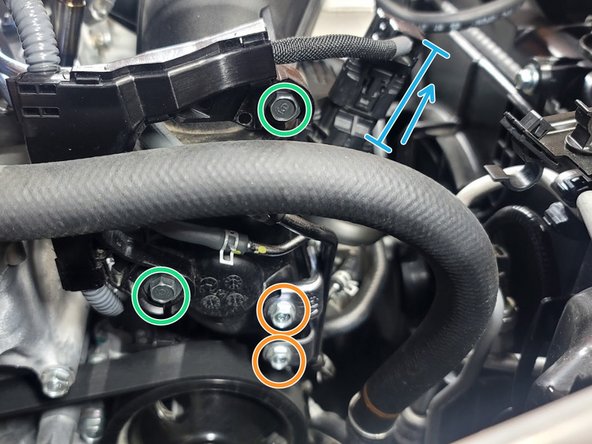

Use 10mm socket and ratchet to remove two (2) bolts from vacuum bracket

-

Use 10mm socket and ratchet to remove two (2) bolts from wiring loom

-

Unplug waste gate actuator by pushing the very top of the clip in with one finger and pulling the plug out with the other hand

-

Set wiring loom out of the way

-

-

-

Use pliers to slide the two (2) hose clamps up the rubber hose

-

Twist each hose to break adhesion to metal tube then and pull both hoses off

-

Use hose pliers if you have them, it's easier

-

Use caution to avoid tearing rubber but it can take some force to free hoses

-

Set hoses out of the way

-

-

-

Use caution not to bend or damage A/C line while removing TIP

-

Be careful not to damage A/C line

-

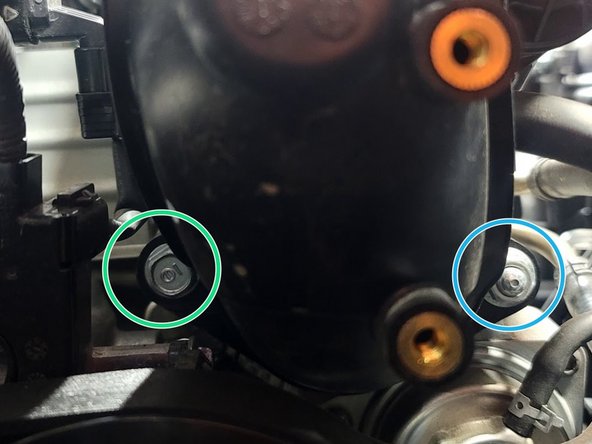

Remove bolt with 12mm socket, 3" extension, and ratchet

-

Remove nut with 12mm socket, 3" extension, and ratchet

-

OE Turbo Inlet Pipe will wiggle freely now

-

-

-

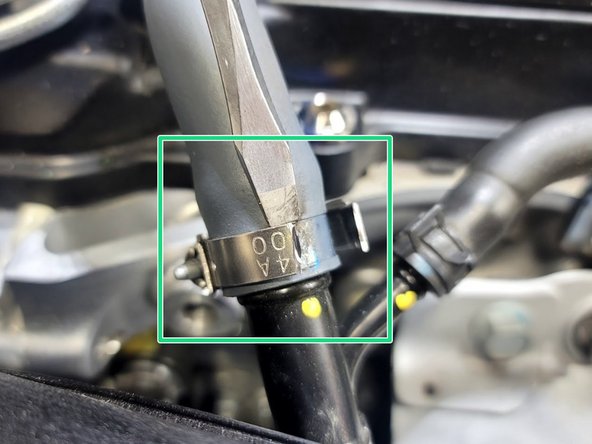

Unfortunately Honda used a single use hose clamps for the turbo inlet pipe. These are difficult to remove

-

Use caution not to damage rubber lines. This is tricky

-

You can use a grinder, Dremel, or perhaps even shears to remove this single use clamp. We prefer Dremel

-

Remove Clamp Shown

-

Partially cut through band of clamp. The idea is to remove enough material that the clamp will break

-

Place flat head screwdriver under cut. If cut enough band will break pretty easily with a bit of pressure

-

-

-

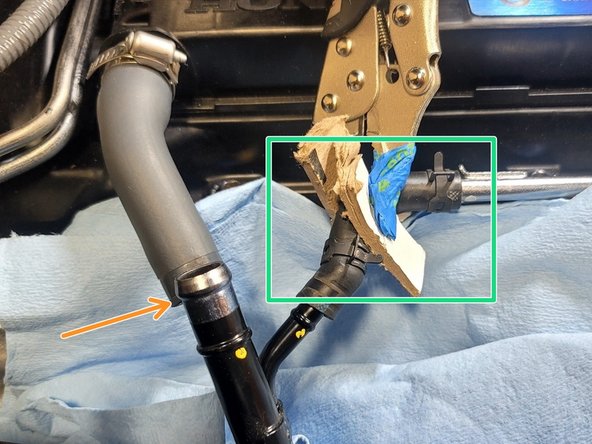

Pop crank breather hose off as shown

-

Use caution as you proceed to minimize coolant leaks

-

Pinch off coolant line in a manner similar to what is shown

-

There are various other tools and ways to accomplish this, like pinch or hose pliers

-

Put towel under coolant line to catch leak

-

Use pliers to slide clamp out of the way as shown

-

Remove rubber upper coolant hose from the TIP hard line

-

Set entire line and assembly out of the way

-

-

-

Plug coolant line attached to TIP with finger while removing TIP so as to avoid further coolant spills

-

Remove OE TIP from car and set aside

-

-

-

Using pliers, remove spring clamp from vacuum line leading to the BPV by sliding it up. Then disconnect the line from the OEM BPV by pulling up on it

-

Set metal vacuum assembly & line aside

-

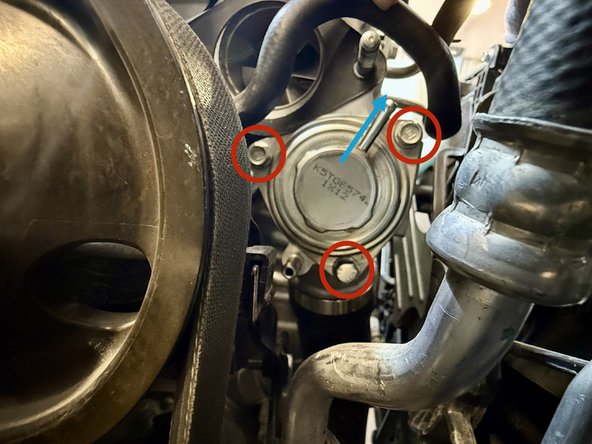

Note the type of fastener used to secure BPV to your Turbocharger

-

For OE style fastener (not shown), use 3/8" ratchet, 3" extension and T30 Torx socket to remove the screws. Alternatively, you can use a T30 Torx T-Handle tool

-

If OE Torx fasteners are stripped, removal of the turbocharger is necessary. Torx bit fasteners can more easily be removed from the BPV if the turbocharger assembly is out of the vehicle

-

Note the orientation of the BPV nipple. The 27WON BPV will need the nipple facing the same way once installed

-

-

-

Top-side

-

Nipple

-

Bottom-side

-

O-rings & Mounting Hardware

-

Need to add spare lube & clamp

-

-

-

Apply a small amount of supplied lubricant or engine oil to both O-rings prior to installation

-

Insert large O-ring into groove on bottom-side and press down firmly to secure

-

Insert small O-ring into groove on bottom-side and press down firmly to secure

-

-

-

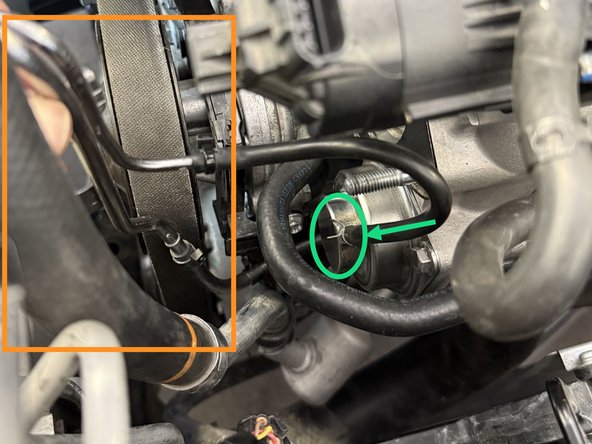

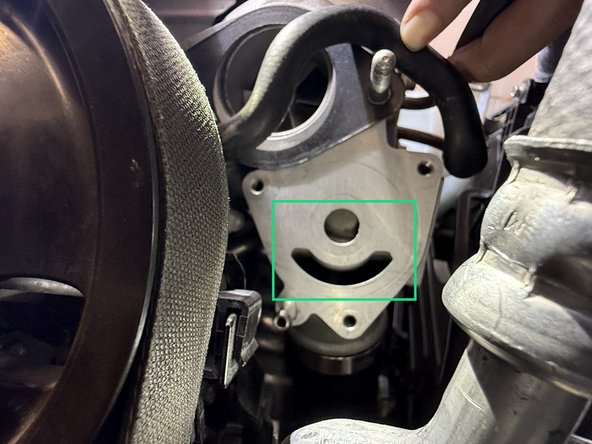

Note the location of the openings on the turbocharger flange. These must align with the 27WON BPV during installation

-

Optional: use a zip tie (not included) to secure coolant line out of the way as shown

-

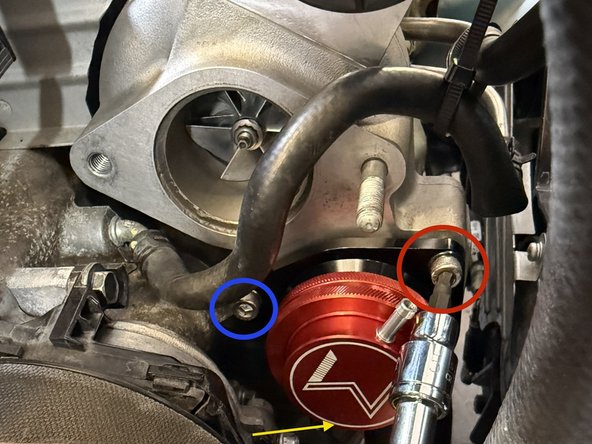

Using a 5mm ball end hex socket and 3” extension, guide the first fastener through the BPV mounting hole and thread onto turbocharger. Leave finger tight

-

Move counterclockwise and thread 2nd fastener until finger tight

-

The last mounting hole is underneath and not visible. Using your fingers, hand thread remaining fastener into the turbocharger. Leave finger tight

-

Torque all three mounting bolts to 7-9 ft-lbs with ratchet

-

Optional: Remove zip tie holding coolant line in place

-

-

-

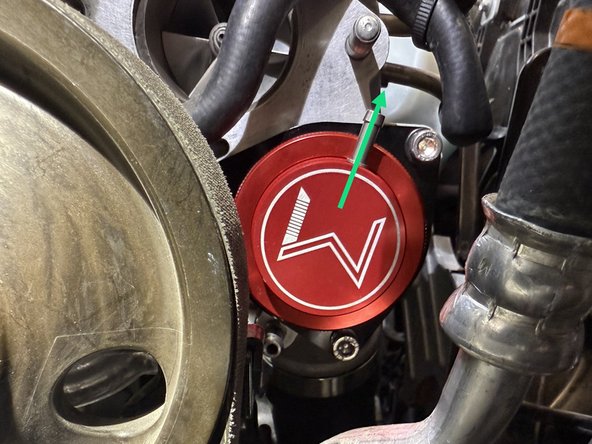

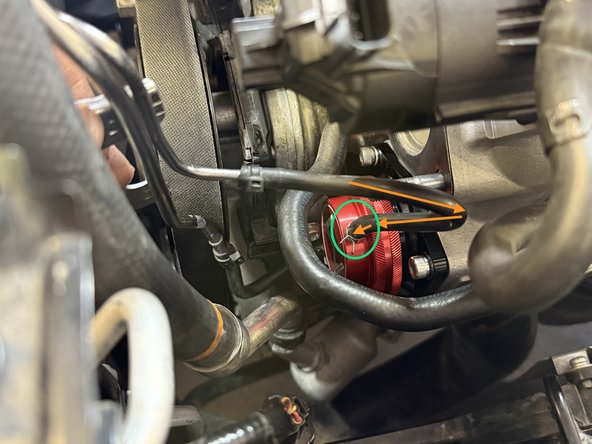

Confirm BPV fitting is pointed in direction as shown. Adjust if needed

-

To adjust nipple position loosen the knurled ring 1-2 turns

-

Once loose, rotate the top portion "W" until proper alignment is achieved. Hold top "W" portion in place while rotating knurled ring in opposite direction to tighten

-

-

-

Re-attach vacuum line onto your new 27WON BPV

-

Using a set of pliers, slide down spring clamp to secure line to BPV

-

-

-

Place TIP back in car as shown. You'll secure it later

-

-

-

Reinstall crank breather hose using provided worm drive clamp as shown

-

Slide rubber coolant line onto hard line

-

Slide clamp in place to secure coolant line

-

Remove clamp preventing leak from upper coolant hose

-

-

-

Be careful not to damage A/C line

-

Wiggle OE TIP into position as shown

-

Reinstall both OE bolt and nut securing TIP to turbo with 12mm socket, 3" extension, and ratchet. Torque to 15-19 ft-lbs

-

Using 10mm socket and ratchet reconnect TIP to bracket near TIP inlet

-

-

-

Route rubber hoses as shown and insert them into the clips

-

Reinstall two (2) screws into Turbo Inlet Pipe (TIP) with T30 Torx Bit to secure EVAP valve

-

-

-

Slide both rubber vacuum lines over hard lines

-

Slice clamps over rubber lines to secure

-

Use 10mm socket and both OE bolts to reattach OE vacuum hard lines to TIP

-

-

-

Plug in WGA

-

Reinstall both OE bolts into wiring loom with 10mm socket and ratchet

-

Put OE coolant tank back into original position in bracket

-

-

-

Reinstall accordion intake tube and tighten clamps with 5.5mm socket

-

-

-

The 27WON BPV is designed to provide OE like boost control and trouble free operation. Periodic service is necessary. If the valve is not serviced it may cease to perform correctly. This could shorten the life of your turbocharger. See instructions at the end of this guide for BPV service

-

BPV service should happen around every third oil change (12,000-15,000 miles). Spare lubrication is included for this

-

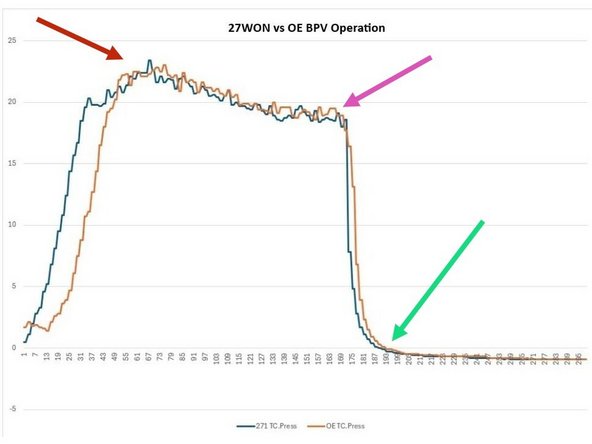

This chart shows good BPV operation for both the OE BPV and the 27WON BPV. Your boost control should look something like this

-

Notice there is not a spike in boost pressure as the turbocharger spools up

-

Notice there is not a spike in pressure when letting off throttle

-

Notice the time to go from purple arrow to green arrow. This is time to vent TC pressure. You see 27WON and OE are very similar

-

-

-

Improper BPV operation can trigger CEL

-

P2261: Turbocharger BPV Issue. This may trigger for reasons not related to BPV. Check boost control using the example on the previous step to make sure your BPV is working properly. OE BPV can throw this code when the rubber seal tears

-

A properly functioning BPV will make some noises when it vents. With an OE intake you might not hear these. With an open filter intake you'll hear all the noises. A "Psssst" or "whooshing" sound is normal

-

If your turbocharger is not able to vent quick enough (for various reasons) it can make an audible noise. This 'flutter' or 'choo choo' sound is from compressor surge. This can reduce the life of the turbocharger. If you hear this noise, check out your entire boost control system including BPV

-

Watch this video https://www.youtube.com/watch?v=2QaajARc... at around 15-17s there is an example of compressor surge from the throttle plate closing

-

-

-

This completes the installation of your 27WON BPV

-

We hope you were impressed with your 27WON experience and love your new parts for years to come. Email us at sales@27won.com or call us at 571-271-0271 with any questions or concerns

-

Please leave a review here: https://store.27won.com/1-5t-10th-and-11...?

-

Share your experience using #27WON on Instagram and Facebook

-

Continue to the next steps for cleaning and lubrication of BPV

-

-

-

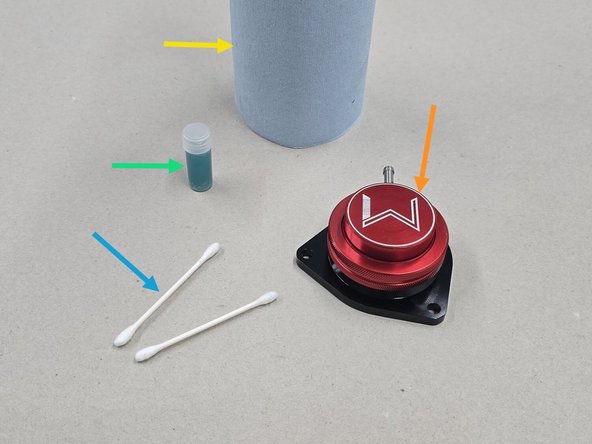

The 27WON BPV will require maintenance every three oil changes or so depending your driving conditions

-

If you are constantly driving in dusty environments we recommending bumping your maintenance up to two oil changes or so

-

To perform maintenance properly, you will need the following items

-

27WON BPV removed from your vehicle

-

Clean paper towels / shop towels

-

Provided vial of high temp grease

-

A couple of Q-tips, or another instrument for applying the grease

-

-

-

Twist the knurled ring on the BPV counter clockwise to loosen the BPV cap as shown

-

Remove the cap and set it to the side

-

Flip the BPV over and press on the center of the internal piston as shown

-

It is important to press as close to the center as possible. If the piston is pressed off to one side it can become crooked and stuck inside of the BPV

-

With the BPV fully disassembled, wipe all of the parts clean with shop towels

-

You can use a cleaning solution here if your BPV is especially dirty, just make sure any solution is fully wiped out before you apply grease to the internal components

-

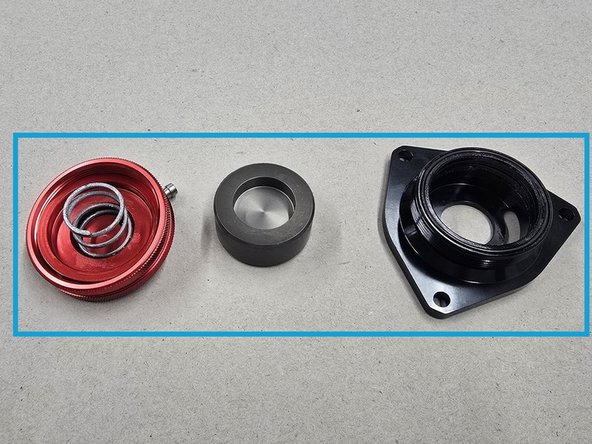

-

-

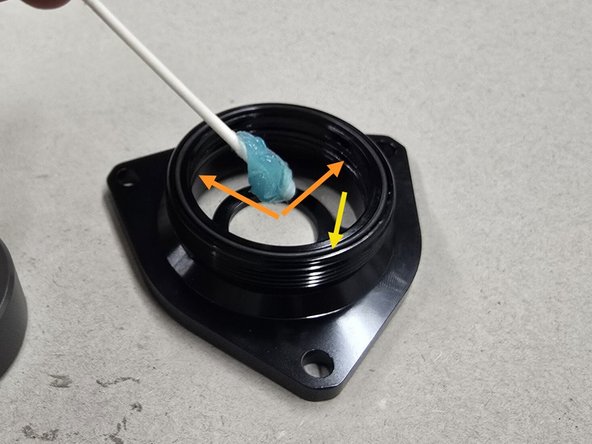

With the components all clean, generously apply the provided grease as shown:

-

Inside of BPV body

-

BPV upper o-ring

-

BPV piston

-

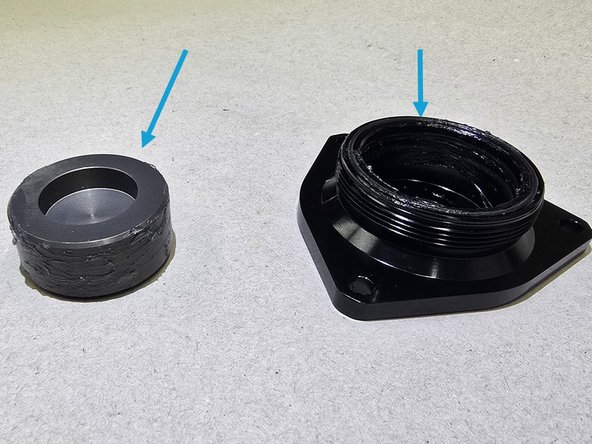

Properly lubed components should appear as shown

-

-

-

Insert the piston back into the BPV body in the orientation shown

-

Just as when it came out, the piston will need to pressed in as even as possible

-

Place the BPV cap back onto the body as shown

-

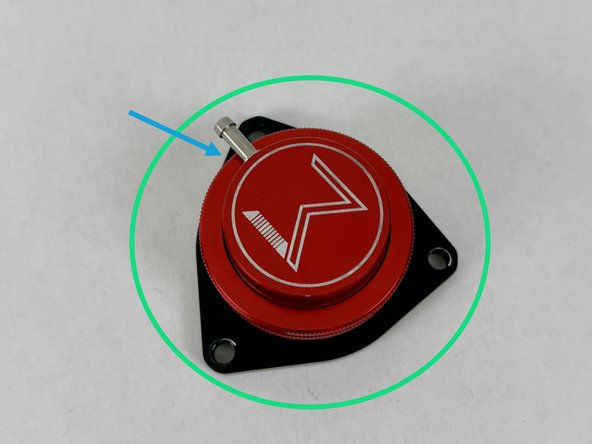

Ensure the BPV spring sits inside of the piston indent circled in green

-

Hand tighten the knurled ring onto the BPV body as shown

-

Use your finger to push the piston from the bottom a few times. The piston should return smoothly to the closed position

-

Reinstall your 27WON BPV!

-